Advanced Ceramic Composites for Sale: Materials for Extreme Environments

The global market for advanced materials is witnessing a significant surge in demand for ceramic matrix composites (CMCs). These materials, available for industrial and research procurement, represent a paradigm shift in material science, offering unparalleled combinations of lightness, strength, and thermal stability. For engineers and procurement specialists seeking ceramic composites for sale, understanding their composition, properties, and applications is crucial for selecting the right material for extreme environment applications.

What Are Ceramic Matrix Composites (CMCs)?

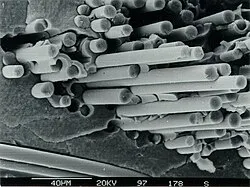

Ceramic composites are engineered materials consisting of a ceramic matrix reinforced with ceramic fibers (such as silicon carbide or carbon fibers). This architecture overcomes the inherent brittleness of monolithic ceramics by introducing mechanisms that absorb energy and stop crack propagation. The result is a material that retains the high-temperature capability, corrosion resistance, and hardness of ceramics while gaining fracture toughness and reliability.

Key Properties and Advantages

When evaluating ceramic composites for sale, several standout properties define their value proposition:

- Exceptional Thermal Resistance: Capable of operating continuously at temperatures exceeding 1200°C (2192°F), where superalloys fail.

- Low Density: Typically one-third the weight of nickel-based superalloys, enabling significant weight savings.

- High Strength and Stiffness: Maintain mechanical integrity under extreme mechanical loads at high temperatures.

- Superior Wear and Corrosion Resistance: Ideal for harsh chemical environments and abrasive applications.

Comparison with Traditional Materials

The following table highlights the performance gap between advanced CMCs and conventional high-temperature materials.

| Material Property | Advanced CMC (SiC/SiC) | Nickel-Based Superalloy | Monolithic Ceramic (Alumina) |

|---|---|---|---|

| Max Use Temperature (°C) | > 1200 | ~ 1150 | ~ 1500 (but brittle) |

| Density (g/cm³) | 2.5 - 3.0 | 8.0 - 9.0 | 3.5 - 4.0 |

| Fracture Toughness (MPa·m¹/²) | 20 - 30 | 50 - 100 | 3 - 5 |

| Primary Advantage | High-temp strength & low weight | Toughness & reliability | Hardness & refractoriness |

Primary Applications Driving Demand

The search for ceramic composites for sale is largely driven by cutting-edge industries pushing performance boundaries.

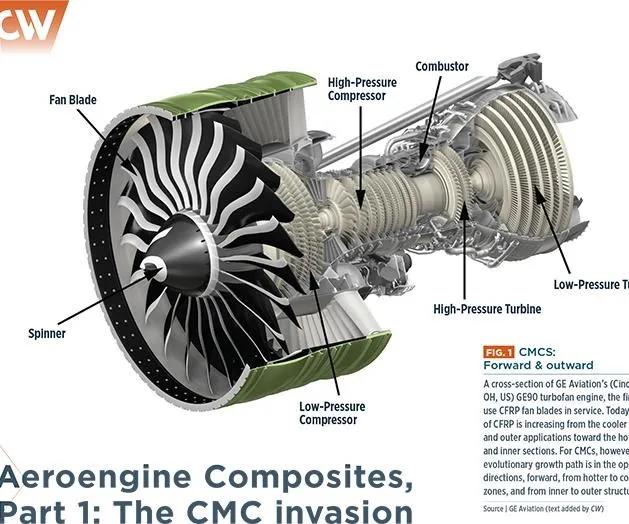

Aerospace and Jet Propulsion

CMC components are revolutionizing jet engine and hypersonic vehicle design. They are used for turbine shrouds, combustor liners, and exhaust nozzles, where their weight savings directly translate into improved fuel efficiency and thrust-to-weight ratios.

Energy and Industrial Systems

In gas turbines for power generation, CMCs allow for higher inlet temperatures, boosting efficiency. They are also critical for heat exchangers, burner parts, and components in advanced nuclear reactors.

Automotive and Friction Systems

High-performance braking systems, especially in motorsports and aviation, utilize carbon-carbon (a subclass of CMC) composites for their fade-resistant braking at extreme temperatures.

Procurement Considerations: Finding the Right Ceramic Composites for Sale

Sourcing these advanced materials requires careful specification. Key parameters include:

- Matrix and Fiber Type: Common systems are SiC/SiC, C/SiC, and Oxide/Oxide composites, each with distinct cost-performance profiles.

- Manufacturing Process: Chemical Vapor Infiltration (CVI), Polymer Infiltration and Pyrolysis (PIP), or Melt Infiltration (MI).

- Form and Delivery: Available as pre-fabricated components, standard shapes, or tailored custom parts.

- Supplier Expertise: Partnering with a manufacturer with proven quality control and application engineering support is vital.

Market Outlook and Future Trends

The market for ceramic composites for sale is projected to grow robustly, driven by decarbonization goals in aerospace and energy. Innovations in additive manufacturing (3D printing) of CMCs are opening doors to more complex, integrated geometries, reducing waste and lead time. Furthermore, development of lower-cost precursor materials and processes aims to broaden their adoption beyond premium sectors into wider industrial applications.

In conclusion, ceramic composites represent a cornerstone of advanced material technology. For organizations operating in extreme environments, procuring the right ceramic composites for sale is not merely a purchase but a strategic investment in performance, efficiency, and technological leadership.