Aerovac Composites One: Revolutionizing Composite Manufacturing

The aerospace and defense industries are constantly evolving, demanding materials that offer superior performance, durability, and efficiency. In this landscape, Aerovac Composites One has emerged as a groundbreaking solution, revolutionizing how composite materials are manufactured and utilized. This advanced composite system represents a significant leap forward in material science, offering unprecedented benefits across various applications.

Understanding Aerovac Composites One Technology

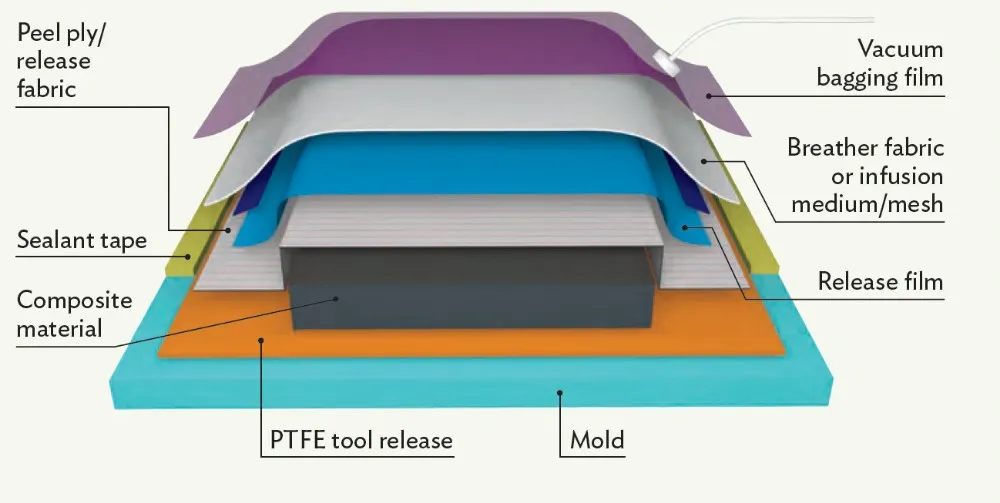

Aerovac Composites One is an innovative vacuum bagging system specifically designed for advanced composite manufacturing. This technology addresses the critical challenges faced in traditional composite production methods, particularly in achieving consistent quality, reducing voids, and ensuring proper resin distribution throughout the composite structure.

The system incorporates advanced membrane technology that allows for superior air and volatiles evacuation while maintaining precise pressure distribution across the entire composite surface. This results in composites with exceptional mechanical properties, reduced porosity, and enhanced structural integrity.

Key Technical Specifications

| Parameter | Specification | Benefit |

|---|---|---|

| Operating Temperature Range | -65°F to 450°F (-54°C to 232°C) | Suitable for various curing cycles |

| Pressure Distribution | Uniform across entire surface | Consistent composite quality |

| Porosity Reduction | Up to 90% improvement | Enhanced structural integrity |

| Material Compatibility | All major resin systems | Versatile application |

Applications in Aerospace Industry

The aerospace sector has been one of the primary beneficiaries of Aerovac Composites One technology. From commercial aircraft to military applications, this advanced composite system has transformed manufacturing processes and component performance.

Aircraft Structural Components

Aerovac Composites One is extensively used in manufacturing critical aircraft structural components, including wing skins, fuselage sections, and empennage structures. The technology ensures these components meet the stringent requirements for weight, strength, and durability demanded by modern aviation standards.

Interior Applications

Beyond structural elements, the system is also employed in creating aircraft interior components such as cabin panels, overhead bins, and seating structures. The consistent quality and surface finish achieved through Aerovac Composites One make it ideal for applications where both performance and aesthetics are crucial.

Performance Advantages and Benefits

| Advantage | Impact | Industry Benefit |

|---|---|---|

| Reduced Porosity | Improved mechanical properties | Enhanced safety and reliability |

| Consistent Quality | Repeatable manufacturing results | Reduced rejection rates |

| Faster Processing | Reduced cycle times | Increased production capacity |

| Material Efficiency | Optimized resin usage | Cost reduction |

Environmental and Economic Impact

Aerovac Composites One contributes significantly to sustainable manufacturing practices. The system reduces material waste, minimizes energy consumption during curing processes, and extends the service life of composite components through improved quality and durability.

Implementation and Best Practices

Successful implementation of Aerovac Composites One requires careful attention to several key factors. Proper training, equipment calibration, and process optimization are essential for maximizing the benefits of this advanced technology.

Process Optimization Guidelines

Manufacturers should focus on optimizing vacuum pressure levels, temperature profiles, and layup sequences to achieve optimal results. Regular maintenance of vacuum systems and proper storage of consumable materials are also critical for consistent performance.

Future Developments and Industry Trends

The future of Aerovac Composites One looks promising, with ongoing research and development focused on enhancing its capabilities. Emerging trends include integration with automated manufacturing systems, development of smart monitoring technologies, and expansion into new industrial sectors beyond aerospace.

Integration with Industry 4.0

The integration of Aerovac Composites One with Industry 4.0 technologies represents the next frontier in composite manufacturing. Real-time monitoring, data analytics, and predictive maintenance capabilities are being developed to further enhance process control and quality assurance.

Conclusion

Aerovac Composites One has established itself as a transformative technology in the field of advanced composite manufacturing. Its ability to deliver consistent, high-quality results while improving efficiency and reducing costs makes it an invaluable tool for industries demanding the highest standards of material performance. As technology continues to evolve, Aerovac Composites One is poised to play an increasingly vital role in shaping the future of composite material applications across multiple sectors.