Comparative Analysis: Conductive Composites vs Traditional Conductors

This comprehensive analysis explores the fundamental differences, advantages, and limitations between emerging conductive composite materials and established traditional conductors in modern electrical and electronic applications.

Introduction to Conductive Materials

The evolution of conductive materials has been a cornerstone of technological advancement. Traditional conductors, primarily metals like copper and aluminum, have dominated electrical applications for centuries. However, the emergence of conductive composite materials represents a paradigm shift in material science, offering unique properties that address limitations of conventional conductors.

Fundamental Properties and Characteristics

Traditional Conductors

Traditional conductors are characterized by their high electrical conductivity, which stems from the presence of free electrons in their atomic structure. Metals such as copper, silver, and aluminum exhibit excellent electrical conductivity but come with inherent limitations including weight, corrosion susceptibility, and mechanical rigidity.

Conductive Composite Materials

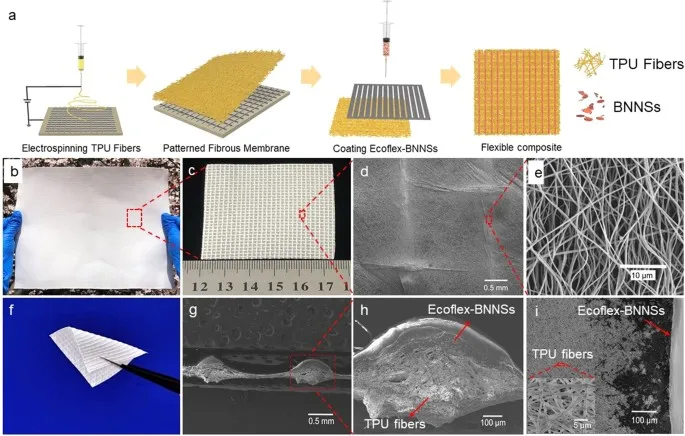

Conductive composites combine conductive fillers (such as carbon nanotubes, graphene, or metal particles) with polymer matrices. This combination creates materials with tailored electrical properties while maintaining the benefits of polymers, including lightweight, corrosion resistance, and design flexibility.

| Property | Traditional Conductors | Conductive Composites |

|---|---|---|

| Electrical Conductivity (S/m) | 10⁶ - 10⁸ | 10¹ - 10⁶ |

| Density (g/cm³) | 2.7 - 8.9 | 1.1 - 2.5 |

| Thermal Conductivity (W/m·K) | 200 - 400 | 0.1 - 50 |

| Corrosion Resistance | Low to Moderate | High |

| Manufacturing Flexibility | Limited | High |

Performance Metrics and Applications

Electrical Performance

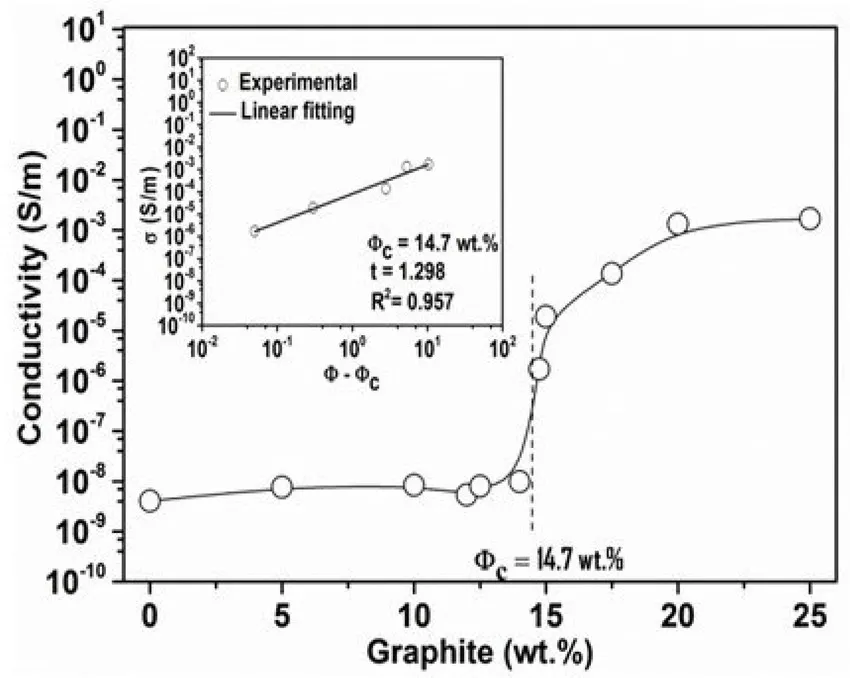

While traditional conductors generally exhibit superior pure electrical conductivity, conductive composites offer adequate performance for many applications with additional benefits. The percolation threshold phenomenon in composites allows for conductivity tuning based on filler concentration and distribution.

Mechanical Properties

Conductive composites excel in mechanical flexibility and impact resistance. Unlike brittle metal conductors, composites can withstand repeated bending and mechanical stress, making them ideal for flexible electronics and wearable technology applications.

Environmental Resistance

The polymer matrix in conductive composites provides excellent resistance to corrosion, chemicals, and environmental degradation. This characteristic significantly extends service life in harsh environments where traditional metals would rapidly deteriorate.

| Application Area | Traditional Conductor Advantages | Conductive Composite Advantages |

|---|---|---|

| Power Transmission | High current capacity, established standards | Lightweight, corrosion resistance |

| Electronics | Excellent conductivity, reliability | Design flexibility, EMI shielding |

| Aerospace | Proven performance | Weight reduction, complex shapes |

| Medical Devices | Biocompatibility (certain metals) | Flexibility, MRI compatibility |

| Automotive | Cost-effectiveness for high-current | Vibration resistance, integration |

Manufacturing and Processing Considerations

Traditional Conductor Manufacturing

Traditional metal conductors typically undergo processes like drawing, extrusion, and rolling. These methods are well-established but energy-intensive and limited in producing complex geometries without secondary operations.

Composite Material Processing

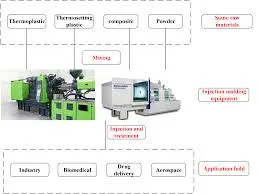

Conductive composites benefit from versatile manufacturing techniques including injection molding, 3D printing, and compression molding. These processes enable complex geometries, integrated features, and reduced assembly requirements.

Cost Analysis and Economic Considerations

The economic landscape differs significantly between material types. Traditional conductors benefit from established supply chains and mature processing technologies, while conductive composites offer potential savings through weight reduction, integrated manufacturing, and reduced maintenance costs.

Future Trends and Development Directions

Material Innovation

Ongoing research focuses on enhancing the electrical properties of composites through novel fillers like MXenes, improved dispersion techniques, and hybrid filler systems. These developments aim to bridge the conductivity gap with traditional metals.

Sustainability Aspects

Conductive composites offer potential environmental benefits through reduced material usage, lighter weight contributing to energy savings in transportation, and recyclability advancements in polymer matrices.

Conclusion: Strategic Material Selection

The choice between conductive composite materials and traditional conductors depends on specific application requirements. Traditional conductors remain optimal for high-current applications where maximum conductivity is paramount. Conductive composites excel in applications requiring lightweight, corrosion resistance, design flexibility, and multifunctional capabilities. The future likely involves synergistic use of both material types, leveraging their respective strengths in hybrid systems.

As material science advances, the performance gap continues to narrow, making conductive composites increasingly viable for a broader range of applications while traditional conductors evolve to meet new challenges in efficiency and sustainability.