Comprehensive Guide to Metallic Materials: Properties and Applications

Introduction to Metallic Materials

Metallic materials represent one of the most crucial categories of engineering materials, characterized by their excellent electrical and thermal conductivity, mechanical strength, and malleability. These materials form the backbone of modern industrial civilization, finding applications across virtually every sector from construction and transportation to electronics and medical devices. The strategic selection of appropriate metallic materials is fundamental to engineering design and manufacturing processes worldwide.

Classification of Metallic Materials

Metallic materials can be systematically categorized based on their composition, structure, and properties. Understanding these classifications is essential for material selection in engineering applications.

Ferrous Metals and Alloys

Ferrous metals contain iron as their primary constituent and represent the most widely used category of metallic materials in industrial applications.

| Material | Composition | Key Properties | Primary Applications |

|---|---|---|---|

| Carbon Steel | Iron + 0.05-2.1% Carbon | High strength, good machinability | Construction, automotive, machinery |

| Stainless Steel | Iron + Chromium (min 10.5%) | Corrosion resistance, hygiene | Food processing, medical, architecture |

| Cast Iron | Iron + 2-4% Carbon + Silicon | Excellent castability, wear resistance | Engine blocks, pipes, machine tools |

| Tool Steel | Iron + Tungsten/Molybdenum/Vanadium | High hardness, heat resistance | Cutting tools, dies, molds |

Non-Ferrous Metals

Non-ferrous metals contain no iron as their primary constituent and offer distinct advantages including corrosion resistance, lighter weight, and non-magnetic properties.

Aluminum and Its Alloys

Aluminum represents the second most used metallic material after steel, prized for its excellent strength-to-weight ratio and corrosion resistance.

| Alloy Series | Primary Alloying Elements | Characteristics | Common Applications |

|---|---|---|---|

| 1xxx Series | 99% Pure Aluminum | Excellent corrosion resistance, high conductivity | Electrical conductors, chemical equipment |

| 2xxx Series | Copper | High strength, aerospace quality | Aircraft structures, truck wheels |

| 5xxx Series | Magnesium | Good weldability, marine corrosion resistance | Marine applications, pressure vessels |

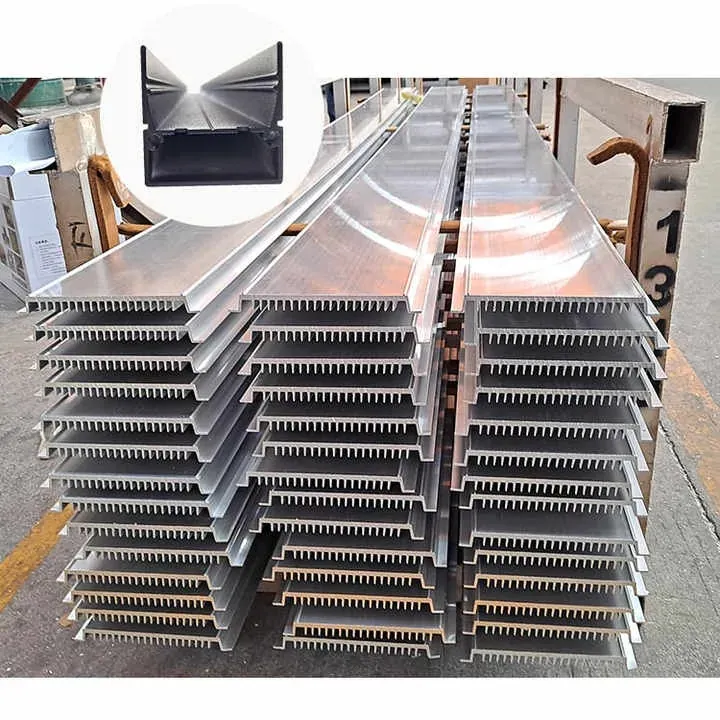

| 6xxx Series | Magnesium and Silicon | Medium strength, excellent extrudability | Architectural extrusions, automotive |

| 7xxx Series | Zinc | Highest strength, heat treatable | Aircraft components, sports equipment |

Copper and Copper Alloys

Copper and its alloys are valued for their excellent electrical and thermal conductivity, corrosion resistance, and antimicrobial properties.

Titanium and Its Alloys

Titanium offers an exceptional combination of high strength, low density, and outstanding corrosion resistance, making it ideal for demanding applications.

| Alloy Designation | Composition | Key Features | Applications |

|---|---|---|---|

| Commercially Pure Ti | 99.2% Ti minimum | Excellent corrosion resistance | Chemical processing, marine |

| Ti-6Al-4V | Ti + 6% Al + 4% V | High strength, good fatigue resistance | Aerospace, biomedical implants |

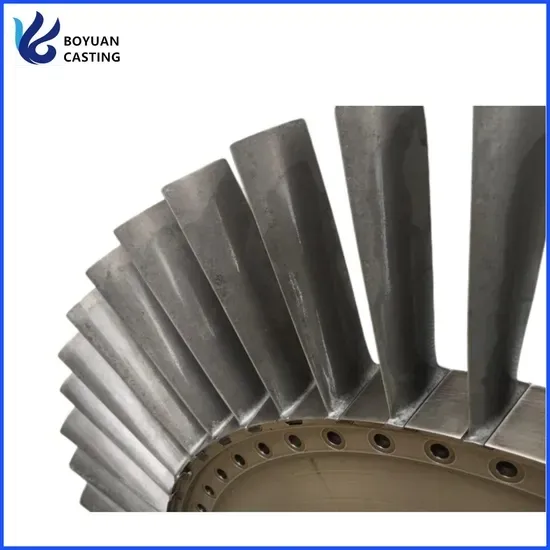

| Ti-6Al-2Sn-4Zr-2Mo | Ti with multiple alloying elements | High temperature capability | Jet engine components |

Specialty and Advanced Metallic Materials

Superalloys

Superalloys are high-performance materials designed to withstand extreme temperatures and corrosive environments while maintaining mechanical integrity.

Shape Memory Alloys

These innovative materials can return to their original shape after deformation when exposed to specific thermal conditions, enabling unique applications in medical devices and aerospace.

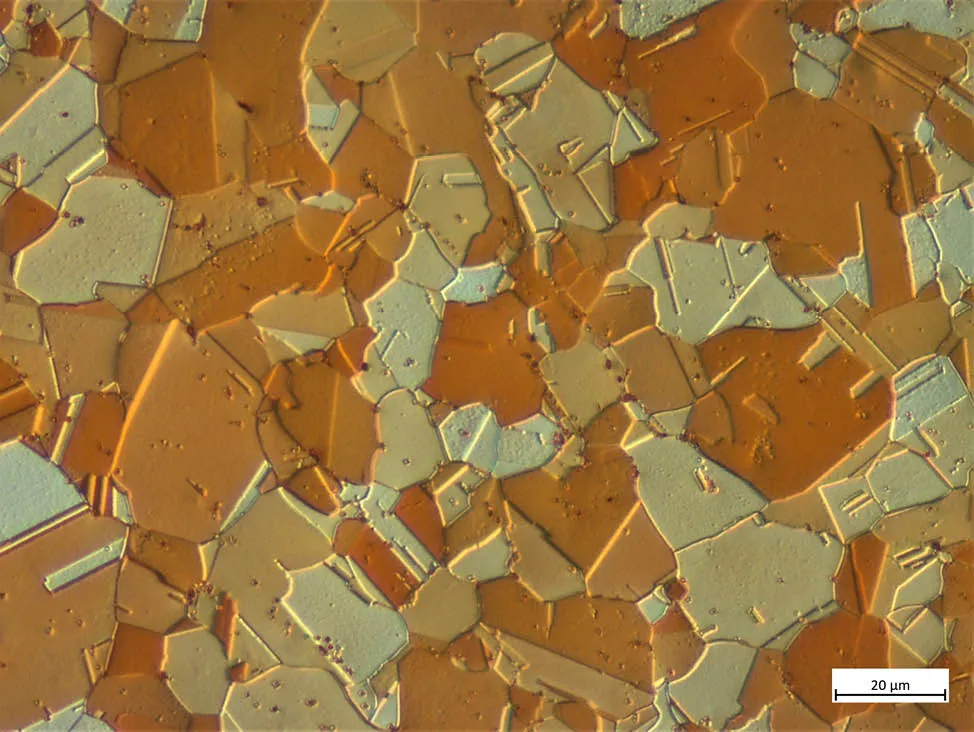

Amorphous Metals (Metallic Glasses)

Amorphous metals possess a non-crystalline structure, resulting in exceptional strength, elasticity, and corrosion resistance compared to their crystalline counterparts.

Material Selection Criteria

The selection of appropriate metallic materials involves careful consideration of multiple factors to ensure optimal performance and cost-effectiveness.

| Selection Factor | Considerations | Impact on Choice |

|---|---|---|

| Mechanical Properties | Strength, hardness, ductility, toughness | Determines load-bearing capacity and durability |

| Physical Properties | Density, thermal/electrical conductivity | Affects weight, heat management, electrical performance |

| Corrosion Resistance | Environmental compatibility, maintenance requirements | Influences lifespan and maintenance costs |

| Manufacturability | Machinability, weldability, formability | Affects production methods and costs |

| Cost Considerations | Material cost, processing cost, lifecycle cost | Determines economic feasibility |

Future Trends in Metallic Materials

Advanced High-Strength Steels (AHSS)

The development of advanced high-strength steels continues to evolve, offering improved strength-to-weight ratios for automotive and transportation applications.

Additive Manufacturing Alloys

Specialized metallic powders optimized for 3D printing processes are enabling complex geometries and customized components across industries.

Sustainable and Recyclable Alloys

Growing emphasis on circular economy principles is driving the development of easily recyclable alloys and manufacturing processes with reduced environmental impact.

Conclusion

The comprehensive understanding of metallic materials, from traditional ferrous alloys to advanced specialty metals, remains fundamental to technological progress across all industrial sectors. As material science continues to advance, new metallic materials with enhanced properties and sustainability profiles will emerge, enabling innovative applications and addressing global challenges in energy, transportation, and infrastructure development.