Corrosion Resistance and Encapsulation Technologies for Metallic Phase-change Materials

Metallic Phase-Change Materials (MPCMs), such as alloys of aluminum, magnesium, zinc, and tin, have emerged as promising candidates for high-density thermal energy storage due to their high latent heat of fusion, excellent thermal conductivity, and relatively constant phase-change temperatures. However, their practical application in systems like concentrated solar power, waste heat recovery, and electronic thermal management is significantly hindered by two primary challenges: corrosion and containment during repeated solid-liquid cycles. This article delves into the corrosion mechanisms affecting MPCMs and reviews the latest encapsulation technologies designed to overcome these barriers.

Corrosion Challenges in Metallic PCMs

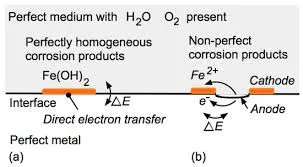

Corrosion in MPCMs can be categorized into two main types: chemical corrosion from reaction with the environment (e.g., oxygen, moisture) and galvanic corrosion when the PCM is in contact with a dissimilar container material. The high temperatures during melting phases accelerate these reactions, leading to material degradation, loss of storage capacity, and potential system failure.

Key factors influencing corrosion rates include:

- PCM composition and impurity content.

- Operating temperature range and cycling frequency.

- Nature of the container or encapsulant material.

- Presence of oxygen and other corrosive agents in the operating environment.

Strategies for Enhancing Corrosion Resistance

1. Alloying and Surface Modification

Modifying the PCM itself can improve inherent resistance. Adding small amounts of elements like silicon or rare earth metals to aluminum-based PCMs can form protective oxide layers. Surface treatments, such as anodizing or applying conversion coatings, create a passive barrier against environmental attack.

2. Protective Coatings on Containers

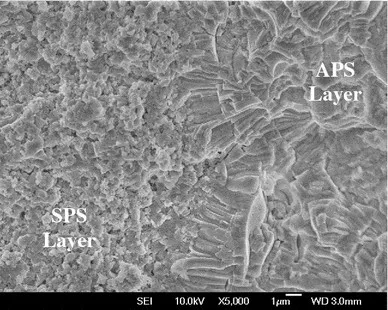

The internal surface of containment vessels (often steel or aluminum) can be coated with inert layers. Ceramic coatings (e.g., alumina, silica via sol-gel processes) and high-temperature polymer coatings are effective in preventing direct contact between the molten metal and the container wall.

Encapsulation Technologies for MPCMs

Encapsulation involves creating a physical shell around the PCM, isolating it from the environment and providing structural stability. This is critical for handling volume change during phase change and preventing leakage.

| Technique | Materials Used | Advantages | Challenges | Suitability for MPCMs |

|---|---|---|---|---|

| Macro-encapsulation | Stainless steel, aluminum capsules, panels | High mechanical strength, easy integration | Risk of corrosion at interface, limited surface area for heat transfer | High (for large-scale storage) |

| Micro-encapsulation | Oxide ceramics (Al2O3, SiO2), carbon | Large heat transfer area, reduces supercooling | Complex synthesis, shell stability at high T, cost | Medium (under active R&D) |

| Matrix Encapsulation/Form-stable PCMs | Porous ceramic, carbon foam, metal matrix | No leakage, good thermal conductivity, shape stability | PCM loading capacity, potential reactivity with matrix | Very High (promising approach) |

| Hybrid & Multi-layered Encapsulation | Combination of polymer, ceramic, and metal layers | Synergistic protection, balances strength and barrier properties | Fabrication complexity and cost | High (for demanding applications) |

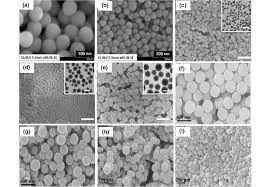

Micro-encapsulation and Nano-encapsulation

These techniques involve coating microscopic or nanoscopic droplets of MPCM with a thin, durable shell. Methods like in-situ polymerization or sol-gel processes are used to create shells from silica or alumina. This approach maximizes heat transfer surface area but requires shells that can withstand internal pressure from the melting metal and resist thermal stress.

Matrix Encapsulation

Here, the molten MPCM is infiltrated into a pre-formed, porous, and mechanically stable matrix (e.g., silicon carbide foam, graphite network). The capillary forces within the pores retain the liquid PCM, creating a leak-free, form-stable composite. The matrix must be chemically compatible and wetted by the PCM.

Future Perspectives and Conclusion

The future of MPCM technology lies in developing cost-effective, scalable, and ultra-reliable encapsulation solutions. Research is trending towards smart multi-functional capsules that combine corrosion inhibition, high thermal conductivity, and self-healing properties. Advanced characterization tools and computational modeling are essential for understanding long-term degradation mechanisms under thermal cycling.

In conclusion, while metallic PCMs offer unparalleled performance metrics for thermal energy storage, their successful commercialization is intrinsically linked to solving the dual problem of corrosion and encapsulation. Through innovative material engineering and hybrid protection strategies, these challenges are being progressively overcome, paving the way for more efficient and durable thermal energy systems.