Corrosion Resistance in High-Performance Magnetic Alloys

High-performance magnetic alloys are critical components in modern technology, enabling advancements in electronics, energy generation, and transportation. While magnetic properties like coercivity, remanence, and permeability often take center stage, corrosion resistance is equally vital for ensuring longevity and reliability. This article explores the mechanisms, challenges, and strategies for enhancing corrosion resistance in magnetic alloys, with a focus on widely used materials such as neodymium-iron-boron (NdFeB), samarium-cobalt (SmCo), alnico, and silicon steel.

1. The Importance of Corrosion Resistance in Magnetic Alloys

Magnetic alloys are frequently deployed in harsh environments—ranging from humid atmospheres to high-temperature industrial settings—where corrosion can degrade magnetic performance and structural integrity. Corrosion-induced failures lead to increased maintenance costs, reduced efficiency, and potential safety hazards. For instance, in electric vehicle motors or wind turbine generators, corrosion of permanent magnets can result in significant energy losses and operational downtime. Thus, enhancing corrosion resistance is paramount for extending service life and maintaining performance.

Micrograph showing corrosion pits in a NdFeB magnet after exposure to humid conditions, highlighting the need for protective coatings.bbbb

Micrograph showing corrosion pits in a NdFeB magnet after exposure to humid conditions, highlighting the need for protective coatings.bbbb

2. Corrosion Mechanisms in Magnetic Alloys

Corrosion in magnetic alloys primarily occurs through electrochemical processes, influenced by composition, microstructure, and environmental factors. Key mechanisms include:

2.1 Galvanic Corrosion

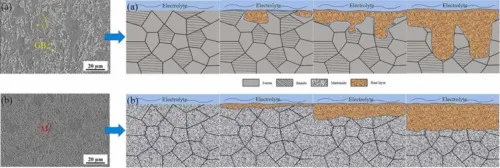

Many magnetic alloys comprise multiple phases with varying electrochemical potentials. In NdFeB magnets, the neodymium-rich phase is highly anodic compared to the Nd2Fe14B matrix, leading to preferential dissolution in corrosive environments. This galvanic coupling accelerates degradation, particularly in the presence of electrolytes like saltwater.

2.2 Intergranular Corrosion

Grain boundaries often act as pathways for corrosive agents. In sintered alloys, porosity and impurity segregation at boundaries can initiate cracking and spalling, compromising mechanical strength and magnetic uniformity.

oooo bbbbSchematic illustration of galvanic corrosion between anodic and cathodic phases in a NdFeB magnet.bbbb

bbbbSchematic illustration of galvanic corrosion between anodic and cathodic phases in a NdFeB magnet.bbbb

2.3 Environmental Factors

Temperature, humidity, pH, and pollutant concentrations (e.g., chlorides, sulfides) significantly influence corrosion rates. For example, SmCo magnets exhibit excellent resistance to oxidation at high temperatures but are susceptible to sulfur-containing atmospheres.

3. Corrosion Resistance Strategies

To mitigate corrosion, various strategies are employed, including alloy modification, surface treatments, and protective coatings.

3.1 Alloying Elements

Adding elements like chromium, cobalt, or aluminum can enhance passivation by forming stable oxide layers. In alnico alloys, titanium and cobalt improve both magnetic properties and resistance to oxidation. However, alloying must be balanced to avoid degrading magnetic performance.

| Alloying Element | Effect on Corrosion Resistance | Impact on Magnetic Properties | Common Alloys |

|---|---|---|---|

| Chromium (Cr) | Forms Cr2O3 passive layer; improves oxidation resistance | May reduce saturation magnetization | Stainless steels, SmCo |

| Cobalt (Co) | Enhances stability in acidic environments | Increases Curie temperature and coercivity | SmCo, Alnico |

| Dysprosium (Dy) | Minimal direct effect; often used with coatings | Improves coercivity at high temperatures | NdFeB |

| Aluminum (Al) | Forms protective Al2O3 scale | Can reduce magnetic moment | Alnico, Fe-Cr-Al alloys |

3.2 Protective Coatings

Coatings are the most common method for safeguarding magnetic alloys. Options include:

- Metallic Coatings: Nickel, zinc, or aluminum layers provide barrier protection. Electroplated nickel is widely used for NdFeB magnets but requires pore-free deposition to prevent undercutting corrosion.

- Organic Coatings: Epoxies, polymers, or paints offer cost-effective protection against moisture and chemicals, though they may have temperature limitations.

- Conversion Coatings: Phosphating or chromating creates adherent layers that enhance paint adhesion and provide secondary corrosion resistance.

bbbbSEM image showing a multi-layer coating (nickel plus polymer) on a NdFeB magnet, demonstrating effective barrier formation.bbbb

bbbbSEM image showing a multi-layer coating (nickel plus polymer) on a NdFeB magnet, demonstrating effective barrier formation.bbbb

3.3 Surface Engineering

Techniques like laser cladding, physical vapor deposition (PVD), or chemical vapor deposition (CVD) enable the application of dense, corrosion-resistant layers without compromising magnetic properties. For instance, alumina (Al2O3) coatings deposited via CVD offer excellent protection in high-temperature applications.

4. Case Studies: Corrosion Behavior of Specific Alloys

4.1 NdFeB Magnets

NdFeB magnets exhibit high energy density but are prone to corrosion due to their multi-phase structure and reactive neodymium content. Accelerated testing in salt spray environments reveals significant weight loss without protection. Industry standards often require multi-layer coatings (e.g., Ni-Cu-Ni) for automotive and aerospace applications.

4.2 SmCo Magnets

SmCo alloys demonstrate superior corrosion resistance compared to NdFeB, owing to their cobalt-rich matrix. They withstand temperatures up to 350°C and are less susceptible to humidity. However, they are vulnerable to sulfur dioxide and acidic conditions, necessitating tailored coatings for industrial use.

4.3 Alnico and Silicon Steel

Alnico alloys, with their aluminum-nickel-cobalt composition, form stable oxide layers, making them suitable for elevated temperatures. Silicon steel, used in transformer cores, relies on silicon content (3–4%) for improved resistivity and oxidation resistance, though insulating coatings are applied to minimize eddy current losses.

oooo bbbbComparative graph of corrosion rates (mm/year) for NdFeB, SmCo, and alnico alloys in saline environments.bbbb

bbbbComparative graph of corrosion rates (mm/year) for NdFeB, SmCo, and alnico alloys in saline environments.bbbb

5. Future Directions and Innovations

Research is focused on developing advanced materials with inherent corrosion resistance. Gradient alloys, nanostructured coatings, and self-healing polymers are promising avenues. Additionally, computational modeling aids in predicting corrosion behavior under complex operating conditions, enabling proactive design.

Conclusion

Corrosion resistance is a critical attribute of high-performance magnetic alloys, directly impacting their durability and application scope. Through a combination of alloy design, surface treatments, and protective coatings, manufacturers can mitigate degradation and extend service life. As technology evolves, continued innovation in materials science will further enhance the synergy between magnetic performance and environmental stability.