Future Trends in Lightweight Structural Materials for Renewable Energy Systems

The global transition towards renewable energy sources, such as wind, solar, and hydrogen power, is accelerating. A critical enabler of this shift is the development and deployment of advanced lightweight structural materials. These materials are pivotal for enhancing the efficiency, durability, and economic viability of renewable energy systems. This article explores the emerging trends and future directions in lightweight materials that are set to revolutionize the renewable energy landscape.

1. The Imperative for Lightweighting in Renewable Energy

The core principle behind using lightweight materials is to maximize the energy output while minimizing the resource input and structural load. In wind energy, lighter turbine blades can capture wind energy more efficiently and reduce the load on the tower and nacelle. For solar power, lightweight photovoltaic (PV) panels enable installation on a wider variety of structures, including rooftops with limited load-bearing capacity. In emerging sectors like hydrogen energy, reducing the weight of storage tanks (for compressed or liquid hydrogen) and fuel cell systems is crucial for mobile applications, particularly in transportation.

2. Key Material Classes and Their Applications

Several classes of advanced materials are at the forefront of this innovation.

2.1 Advanced Composites

Carbon fiber-reinforced polymers (CFRPs) and glass fiber-reinforced polymers (GFRPs) are the workhorses of lightweighting. Their high strength-to-weight ratio and excellent fatigue resistance make them ideal for massive wind turbine blades, which can exceed 100 meters in length. The future lies in developing lower-cost carbon fibers, recyclable thermoset resins, and thermoplastic composites that can be melted and reshaped at end-of-life.

2.2 Metal Alloys and Hybrid Structures

Next-generation aluminum and magnesium alloys offer significant weight savings over steel. They are increasingly used in solar panel framing, wave energy converter components, and supporting structures for concentrated solar power (CSP) systems. A key trend is the creation of hybrid structures, where composites are strategically combined with metals to optimize performance and cost-effectiveness. For instance, a turbine blade might have a carbon fiber spar cap for strength and a lighter glass fiber shell.

2.3 Ceramic and Carbon-Carbon Composites

For extreme environments, such as the heat receivers in CSP plants, advanced ceramics and carbon-carbon composites provide exceptional thermal stability and resistance to corrosion while being lighter than traditional refractory metals.

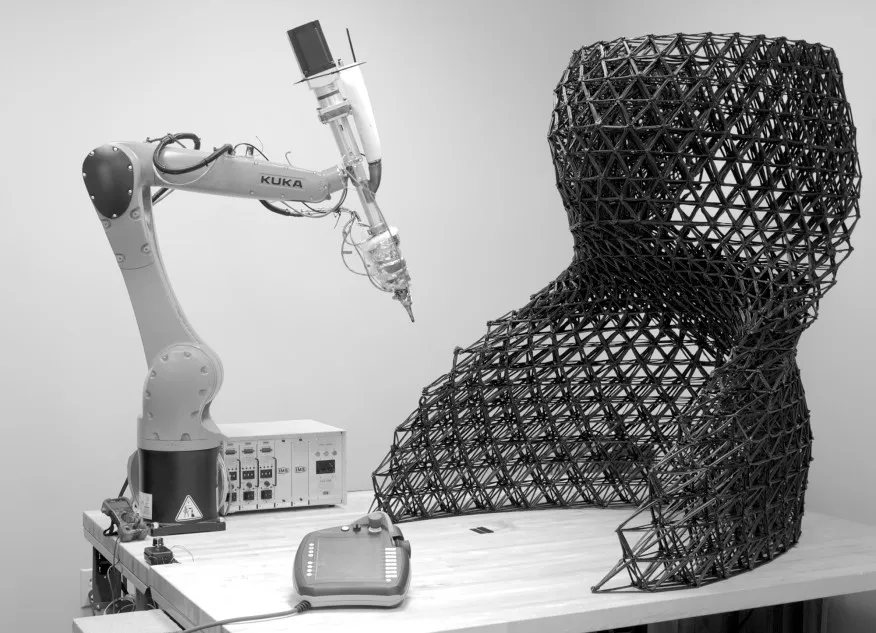

2.4 Additively Manufactured (AM) Materials

3D printing allows for the creation of complex, topology-optimized geometries that are impossible to achieve with traditional manufacturing. This enables the production of components that use the minimal amount of material necessary to perform a function, drastically reducing weight. AM is being explored for lightweight heat exchangers in power plants, custom brackets for solar arrays, and intricate components for hydrogen fuel cells.

| Material Class | Density (g/cm³) | Key Strength | Primary Renewable Application |

|---|---|---|---|

| Structural Steel | 7.85 | High Toughness, Low Cost | Towers, Foundations |

| Aluminum Alloys | 2.70 | Good Strength, Corrosion Resistance | Solar Frames, Support Structures |

| Glass Fiber Reinforced Polymer (GFRP) | 1.8 - 2.1 | High Strength-to-Weight, Cost-Effective | Wind Turbine Blades |

| Carbon Fiber Reinforced Polymer (CFRP) | 1.5 - 1.6 | Exceptional Strength-to-Weight Ratio | Premium Wind Blades, Hydrogen Tanks |

3. Emerging Trends and Future Outlook

The future development of lightweight materials is being shaped by several key trends that extend beyond mere performance.

3.1 Multifunctionality and Integration

The next frontier is materials that are not just structural but also serve other functions. This includes structural battery composites where the material itself stores energy, and composites with embedded sensors for real-time health monitoring of a wind blade or a hydrogen tank, enabling predictive maintenance.

3.2 Sustainability and Circularity

As the renewable energy industry grows, the environmental impact of its materials becomes paramount. Future trends heavily focus on developing recyclable and bio-based composites. This involves designing for disassembly, using thermoplastic matrices, and creating new recycling pathways for carbon fibers to ensure a circular economy for these advanced materials.

3.3 AI-Driven Material Discovery and Design

Artificial intelligence and machine learning are accelerating the discovery of new material formulations and microstructures optimized for specific applications, such as corrosion resistance in offshore environments or high-cycle fatigue in tidal turbines. This significantly shortens the R&D cycle for next-generation materials.

4. Challenges and Considerations

Despite the promise, challenges remain. The high cost of advanced materials like carbon fiber is a significant barrier to widespread adoption. There are also technical hurdles related to joining dissimilar materials (e.g., composites to metals) and ensuring long-term durability in harsh, variable environmental conditions. Furthermore, establishing standardized testing and certification protocols for these novel materials is crucial for gaining industry and regulatory acceptance.

Conclusion

The evolution of lightweight structural materials is intrinsically linked to the advancement of renewable energy systems. The future will be characterized by a move towards smarter, multifunctional, and sustainable materials that are designed with a circular economy in mind. Through continued innovation in composites, metal alloys, additive manufacturing, and material informatics, lightweight solutions will continue to drive down the cost of renewable energy, increase efficiency, and enable new technologies, solidifying their role as a cornerstone of a sustainable energy future.