Graphene Ceramic Composites: Properties and Applications

Graphene ceramic composites represent a groundbreaking class of materials that combine the exceptional properties of graphene with the robustness of ceramic matrices. These composites are gaining significant attention in various high-performance industries due to their enhanced mechanical, thermal, and electrical properties. This article explores the fundamental characteristics, fabrication methods, and diverse applications of graphene ceramic composites, highlighting their potential to transform technology and engineering.

Properties of Graphene Ceramic Composites

The integration of graphene into ceramic matrices results in composites with superior properties compared to traditional ceramics. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, offers high tensile strength, excellent electrical conductivity, and remarkable thermal stability. When embedded in ceramics, it imparts these attributes, leading to materials with improved toughness, wear resistance, and functionality.

Mechanical Properties

Graphene ceramic composites exhibit enhanced mechanical strength and fracture toughness. The addition of even small amounts of graphene (e.g., 0.5-2 wt%) can significantly reduce brittleness, a common limitation of ceramics. For instance, graphene-reinforced alumina shows a 40% increase in fracture toughness due to crack deflection and bridging mechanisms facilitated by graphene sheets.

Thermal and Electrical Properties

These composites also demonstrate improved thermal conductivity and electrical properties. Graphene's high thermal conductivity (up to 5000 W/mK) enhances heat dissipation in ceramics, making them suitable for thermal management applications. Additionally, the electrical conductivity introduced by graphene enables ceramics to be used in electronic devices, where insulation was previously a constraint.

Fabrication Methods

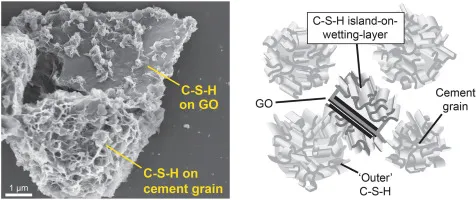

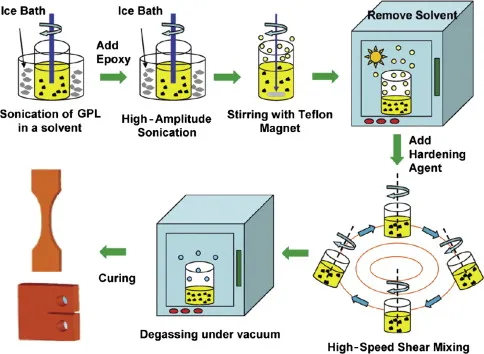

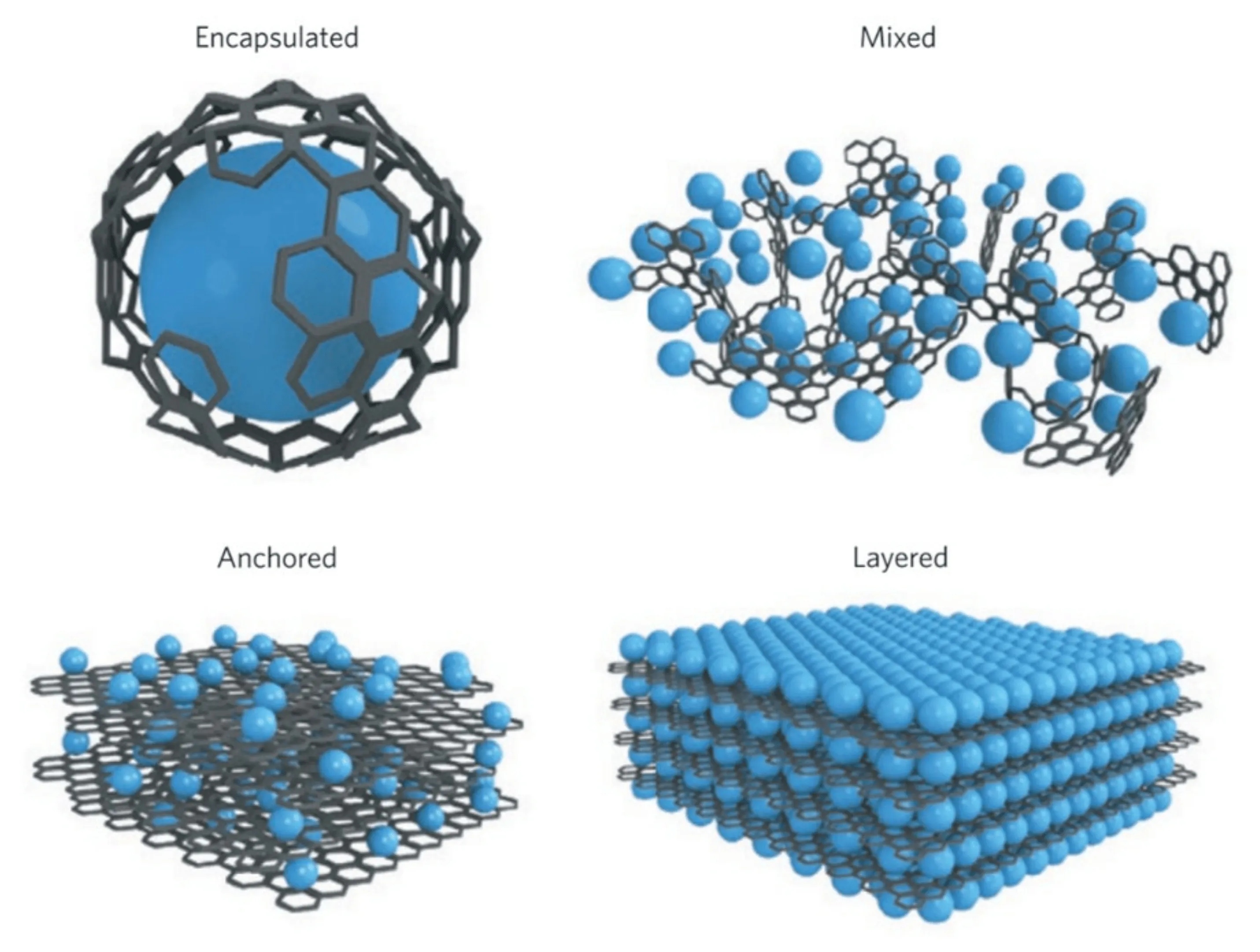

The production of graphene ceramic composites involves several techniques to ensure homogeneous dispersion of graphene within the ceramic matrix. Common methods include powder processing, colloidal processing, and in-situ growth. Powder processing involves mixing graphene oxide or reduced graphene oxide with ceramic powders followed by sintering. Colloidal processing uses suspensions to achieve better dispersion, while in-situ growth involves synthesizing graphene directly on ceramic particles.

| Method | Advantages | Challenges |

|---|---|---|

| Powder Processing | Simple, cost-effective | Risk of agglomeration |

| Colloidal Processing | Better dispersion | Requires stable suspensions |

| In-situ Growth | Uniform distribution | Complex, high temperature |

Applications of Graphene Ceramic Composites

The unique properties of graphene ceramic composites enable their use in a wide range of applications. In aerospace, they are employed in components requiring high strength-to-weight ratios and thermal stability. In electronics, they serve as heat sinks and conductive substrates. Additionally, these composites are used in cutting tools, wear-resistant coatings, and energy storage devices like supercapacitors and batteries.

Energy Storage

Graphene ceramic composites are promising for energy storage due to their high surface area and conductivity. For example, graphene-enhanced ceramic electrodes in batteries improve charge/discharge rates and cycle life. Supercapacitors utilizing these composites exhibit higher energy density and stability.

Biomedical Devices

In the biomedical field, these composites are used for implants and prosthetics owing to their biocompatibility and mechanical properties. Graphene-reinforced hydroxyapatite ceramics, for instance, mimic bone structure and promote osseointegration, making them ideal for orthopedic applications.

Future Perspectives

The future of graphene ceramic composites lies in optimizing fabrication techniques to reduce costs and improve scalability. Research is focused on developing multifunctional composites with tailored properties for specific applications. As technology advances, these materials are expected to play a crucial role in emerging fields like flexible electronics and advanced energy systems.

In conclusion, graphene ceramic composites represent a significant advancement in material science, offering a combination of properties that are unattainable with conventional materials. Their development and utilization continue to expand, driven by ongoing research and industrial innovation.