How Eco-Materials are Shaping Sustainable Infrastructure

The global construction industry stands at a critical juncture. Responsible for a significant portion of energy consumption, raw material extraction, and carbon emissions, it is under immense pressure to reinvent itself. The answer lies not just in smarter design, but fundamentally, in the materials we use. Eco-materials—engineered for minimal environmental impact throughout their lifecycle—are now the cornerstone of a paradigm shift, actively shaping a new era of sustainable, resilient, and circular infrastructure.

The Imperative for Change: Why Traditional Materials Fall Short

Conventional construction materials like ordinary Portland cement and virgin steel have built our modern world, but at a steep ecological cost. Cement production alone accounts for approximately 8% of global CO2 emissions. The linear model of "take, make, dispose" associated with these materials is unsustainable, depleting natural resources and generating enormous waste. Sustainable infrastructure demands materials that reduce embodied carbon, conserve resources, enhance durability, and promote circularity.

Key Eco-Materials Driving the Transformation

A new generation of materials is answering this call, each contributing unique properties to the sustainable infrastructure landscape.

1. Recycled and Secondary Aggregate Concrete

This involves replacing natural aggregates (like gravel and sand) with crushed recycled concrete, glass, or plastic. It dramatically reduces landfill waste and the need for quarrying.

Advanced mixes can incorporate industrial by-products like fly ash (from coal plants) or ground granulated blast-furnace slag (from steel production) as partial cement replacements. These supplementary cementitious materials (SCMs) not only cut carbon emissions but often improve long-term strength and durability.

2. Mass Timber and Engineered Wood Products

Cross-Laminated Timber (CLT) and Glulam are revolutionizing structural design. Acting as a powerful carbon sink, wood stores atmospheric CO2 for the life of the building. It is renewable, has a high strength-to-weight ratio, and allows for faster, quieter construction.

3. Self-Healing Concrete

Infused with bacteria or microcapsules containing healing agents, this innovative material can autonomously repair small cracks. This significantly extends the structure's service life, reduces maintenance needs, and lowers the lifecycle environmental impact by preventing deterioration.

4. Geopolymer Concrete

A near-zero-cement alternative, geopolymer concrete is made by activating industrial aluminosilicate waste materials (like fly ash or slag) with an alkaline solution. It can offer comparable or superior performance to traditional concrete while reducing CO2 emissions by up to 80%.

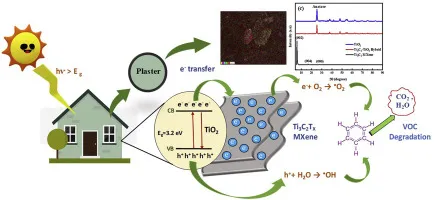

5. Photocatalytic Coatings and Smog-Eating Concrete

These surfaces are treated with titanium dioxide. When exposed to sunlight, they trigger a reaction that breaks down air pollutants like nitrogen oxides into harmless substances, effectively helping to clean the air in urban environments.

Comparative Impact: Eco-Materials vs. Conventional

| Material | Key Sustainable Attribute | Reduction in Embodied Carbon* | Primary Benefit |

|---|---|---|---|

| Traditional Portland Cement Concrete | Baseline | 0% | Widely available, high compressive strength |

| Concrete with 50% SCMs (Fly Ash/Slag) | Industrial By-product Utilization | ~40-50% | Lower carbon, improved durability, cost-effective |

| Cross-Laminated Timber (CLT) | Carbon Sequestration, Renewable | ~60-75% (vs. steel/concrete frame) | Stores CO2, biophilic, fast prefabrication |

| Geopolymer Concrete | Near-Zero Cement | ~70-80% | Very low carbon, high chemical resistance |

| Self-Healing Concrete | Extended Service Life | ~10-30% (lifecycle) | Reduced maintenance, enhanced longevity |

*Estimates are approximate and vary based on mix design, sourcing, and transportation.

The Broader Impact on Sustainable Infrastructure Systems

The integration of eco-materials extends beyond single buildings to shape entire infrastructure systems:

Resilience: Materials like self-healing concrete and corrosion-resistant geopolymers create infrastructure that better withstands environmental stress and climate impacts.

Circular Economy: Using recycled content and designing for deconstruction ensures materials retain value and can be looped back into new projects, minimizing waste.

Urban Livability: Smog-eating concrete and green roofs (using local, permeable materials) directly improve air quality and manage stormwater, creating healthier cities.

Energy Efficiency: Insulating materials from natural or recycled sources (like cellulose insulation) and phase-change materials integrated into building envelopes drastically reduce operational energy needs.

Challenges and the Path Forward

Despite their promise, barriers remain: higher upfront costs in some cases, evolving building codes, supply chain development, and the need for specialized contractor knowledge. Overcoming these requires:

- Policy & Standards: Governments must update codes and offer incentives to favor low-carbon materials.

- Collaborative R&D: Continued innovation to improve performance and cost-effectiveness.

- Industry Education: Training for architects, engineers, and builders on specifying and using eco-materials.

- Lifecycle Assessment (LCA): Mandating holistic LCA to make true environmental performance transparent.

Conclusion: Building the Foundation for a Sustainable Future

Eco-materials are far more than a niche trend; they are the essential building blocks for the infrastructure of the 21st century. By prioritizing materials that are low-carbon, durable, recycled, and regenerative, we construct more than just buildings and bridges—we build resilience against climate change, foster circular economies, and create healthier communities. The transformation of our physical world begins with the very substance of its construction. The widespread adoption of eco-materials is not just shaping sustainable infrastructure; it is laying the foundation for a sustainable future itself.