Innovative Applications of Ceramic Composites in Aerospace Engineering

The aerospace industry has always been at the forefront of materials innovation, constantly seeking materials that can withstand extreme conditions while reducing weight and improving efficiency. Among the most revolutionary materials to emerge in recent decades are ceramic matrix composites (CMCs), which have transformed various aspects of aerospace engineering through their exceptional thermal and mechanical properties.

Fundamental Properties of Ceramic Composites

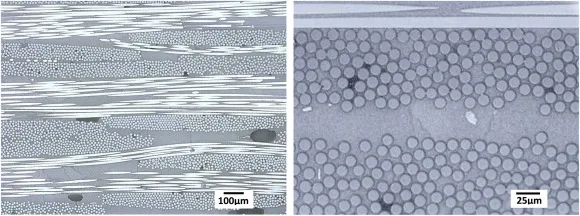

Ceramic matrix composites represent a significant advancement over traditional monolithic ceramics and metallic alloys. These materials combine ceramic matrices with reinforcing fibers, typically carbon or silicon carbide, creating a composite structure that overcomes the inherent brittleness of conventional ceramics while maintaining their excellent high-temperature capabilities.

The key advantages of CMCs include:

- Exceptional thermal stability up to 1650°C

- High strength-to-weight ratio

- Superior oxidation resistance

- Excellent creep resistance

- Low thermal expansion coefficient

Critical Applications in Aircraft Propulsion Systems

Jet Engine Components

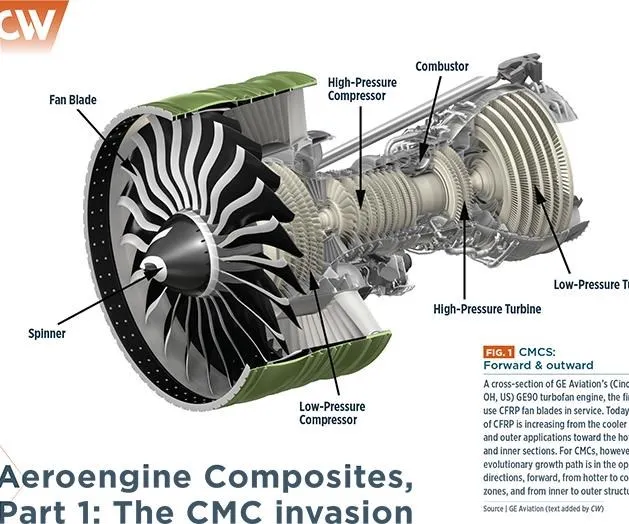

Modern jet engines represent one of the most significant applications for CMCs in aerospace engineering. The relentless pursuit of higher engine efficiency has driven operating temperatures beyond the capabilities of traditional nickel-based superalloys. CMCs have enabled breakthrough improvements in several critical engine components.

Turbine blades and vanes manufactured from silicon carbide (SiC) reinforced CMCs can operate at temperatures approximately 300°C higher than their metallic counterparts. This temperature advantage translates directly into improved fuel efficiency and reduced emissions. Major engine manufacturers like GE Aviation and Rolls-Royce have incorporated CMC components in their latest engine designs, including the LEAP and GE9X engines.

Exhaust Systems and Nozzles

CMC materials have revolutionized exhaust system design by enabling lighter, more durable components that maintain structural integrity at extreme temperatures. The reduced weight of CMC exhaust components compared to traditional metallic systems contributes significantly to overall aircraft weight reduction, while their thermal stability allows for optimized exhaust gas management.

| Material | Maximum Service Temperature (°C) | Density (g/cm³) | Thermal Conductivity (W/m·K) |

|---|---|---|---|

| Nickel Superalloy | 1150 | 8.2 | 12 |

| CMC (SiC/SiC) | 1450 | 2.7 | 15 |

| Carbon-Carbon Composite | 2000 | 1.8 | 40 |

Spacecraft and Hypersonic Vehicle Applications

Thermal Protection Systems

The extreme thermal environments encountered during atmospheric reentry and hypersonic flight demand materials with exceptional thermal stability. CMCs have become the material of choice for leading edges, nose cones, and other critical thermal protection components in spacecraft and hypersonic vehicles.

NASA's Orion spacecraft and various hypersonic research vehicles utilize CMC thermal protection systems that can withstand temperatures exceeding 1600°C while maintaining structural integrity. The materials' ability to withstand thermal shock and their low thermal expansion characteristics make them ideal for these demanding applications.

Rocket Propulsion Components

Rocket engines present some of the most challenging environments for materials, with extreme temperatures, high pressures, and corrosive propellants. CMCs have enabled significant advancements in rocket engine technology through applications in combustion chambers, nozzles, and thrust vector control systems.

Reusable rocket engines, such as those developed by SpaceX and Blue Origin, benefit particularly from CMC components due to their improved thermal cycling resistance and reduced maintenance requirements compared to traditional ablative materials.

Future Developments and Challenges

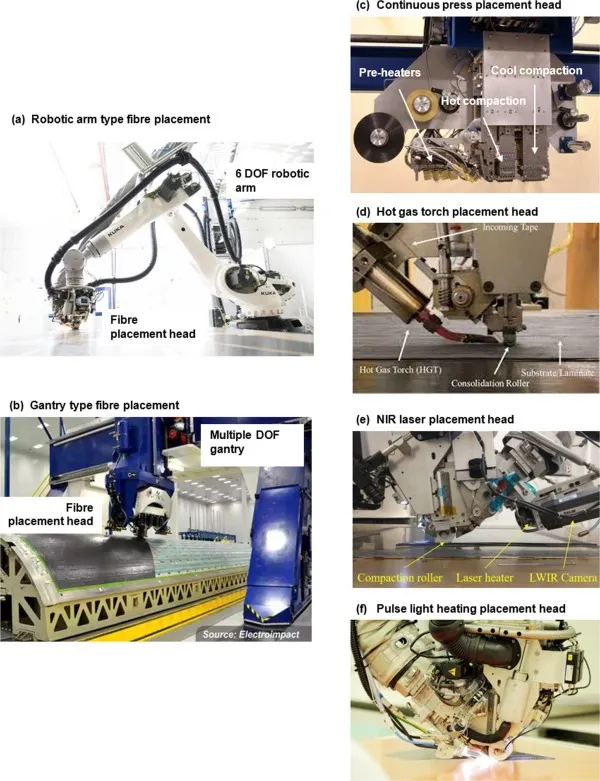

Despite the remarkable progress in CMC technology, several challenges remain for wider adoption in aerospace applications. Manufacturing complexity and cost continue to be significant barriers, though ongoing research in automated manufacturing processes and novel fiber development shows promise for addressing these issues.

Emerging areas of CMC development include:

- Self-healing ceramic composites for extended service life

- Multifunctional CMCs with integrated sensing capabilities

- Environmental barrier coatings for enhanced durability

- Additive manufacturing of complex CMC components

| Research Area | Key Objectives | Potential Impact |

|---|---|---|

| Fiber Development | Higher temperature capability, improved toughness | Extended component life, higher efficiency |

| Manufacturing Innovation | Reduced cost, increased production rate | Broader application, commercial viability |

| Joining Technologies | Reliable CMC-to-metal and CMC-to-CMC joints | More complex component designs |

| Environmental Protection | Enhanced oxidation and corrosion resistance | Operation in harsh environments |

Conclusion

Ceramic matrix composites have established themselves as transformative materials in aerospace engineering, enabling unprecedented performance in propulsion systems, thermal protection, and spacecraft components. As manufacturing technologies advance and costs decrease, the application of CMCs is expected to expand further, driving continued innovation in aerospace design and performance. The ongoing development of these remarkable materials promises to unlock new capabilities in next-generation aircraft and space vehicles, reinforcing their critical role in the future of aerospace engineering.