Lightweight Construction Materials: Revolutionizing Modern Building Design

The construction industry is undergoing a significant transformation with the increasing adoption of lightweight construction materials. These innovative materials offer numerous advantages over traditional heavy construction elements, including reduced structural loads, improved energy efficiency, faster construction times, and enhanced sustainability. As urban populations continue to grow and environmental concerns become more pressing, lightweight materials are emerging as crucial components in the future of sustainable building practices.

Understanding Lightweight Construction Materials

Lightweight construction materials are characterized by their low density while maintaining adequate strength and durability for building applications. These materials typically have densities significantly lower than conventional construction materials like concrete, steel, or brick. The development of lightweight materials represents a convergence of material science, engineering innovation, and sustainable design principles.

The fundamental principle behind lightweight construction is the optimization of material usage to achieve the required structural performance with minimal mass. This approach not only reduces the weight of the building but also decreases the energy required for transportation, handling, and installation. Lightweight materials can be categorized based on their composition, manufacturing process, and specific applications in construction projects.

Key Characteristics of Lightweight Materials

Lightweight construction materials share several common characteristics that make them suitable for modern building applications. These include high strength-to-weight ratios, excellent thermal insulation properties, ease of fabrication and installation, and often, enhanced resistance to environmental factors such as moisture, fire, and pests. Many lightweight materials also offer superior acoustic performance and can be engineered to meet specific architectural and structural requirements.

Major Types of Lightweight Construction Materials

Lightweight Concrete and Composites

Lightweight concrete represents one of the most widely used categories of lightweight construction materials. This material is manufactured by incorporating lightweight aggregates or using foaming agents to create air voids within the concrete matrix. Lightweight concrete offers significant advantages in reducing dead loads on structures while maintaining compressive strength and durability.

Advanced composite materials, including fiber-reinforced polymers (FRP) and carbon fiber composites, are increasingly being used in construction for their exceptional strength-to-weight ratios. These materials are particularly valuable in seismic zones where reducing structural mass can significantly improve earthquake resistance. Composite materials also offer corrosion resistance and can be molded into complex shapes for architectural applications.

Advanced Metal Alloys and Structural Systems

The development of high-strength, lightweight metal alloys has revolutionized structural design in construction. Aluminum alloys, titanium, and advanced steel formulations provide exceptional strength while significantly reducing weight compared to traditional structural materials. These metals are particularly valuable in long-span structures, curtain walls, and modular construction systems.

| Material Type | Density (kg/m³) | Tensile Strength (MPa) | Primary Applications | Sustainability Features |

|---|---|---|---|---|

| Aluminum Alloys | 2,700 | 200-500 | Curtain walls, roofing, structural frames | Highly recyclable, corrosion resistant |

| Titanium Alloys | 4,500 | 900-1,100 | Specialized structures, corrosive environments | Exceptional durability, long service life |

| High-Strength Steel | 7,850 | 500-1,200 | Structural frames, bridges, modular construction | Recyclable, reduced material usage |

| Magnesium Alloys | 1,800 | 200-300 | Temporary structures, interior applications | Lightest structural metal, recyclable |

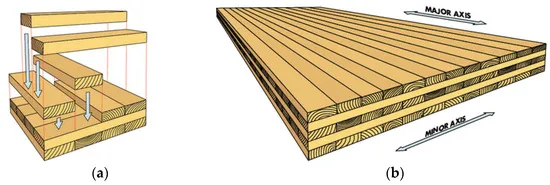

Engineered Wood Products

Engineered wood products represent a sustainable category of lightweight construction materials that have gained significant popularity in recent years. Materials such as cross-laminated timber (CLT), laminated veneer lumber (LVL), and oriented strand board (OSB) offer excellent structural performance while being substantially lighter than concrete or steel alternatives.

These wood-based materials combine the renewable nature of timber with engineered precision and consistency. They contribute to carbon sequestration and can be prefabricated to reduce construction time and waste. The use of engineered wood products is particularly prominent in residential construction, commercial buildings, and increasingly in mid-rise structures.

Benefits and Advantages of Lightweight Construction

Structural and Economic Benefits

The adoption of lightweight construction materials offers numerous structural and economic advantages. Reduced building weight translates to smaller foundation requirements, less structural support, and potential cost savings in both materials and labor. Lightweight materials also enable faster construction cycles through prefabrication and easier handling on-site.

From an economic perspective, lightweight construction can lead to significant savings throughout the building lifecycle. These include reduced transportation costs, lower energy consumption during construction, decreased foundation costs, and in many cases, improved thermal performance that leads to long-term energy savings for building occupants.

Environmental and Sustainability Advantages

Lightweight construction materials contribute substantially to sustainable building practices and environmental protection. The reduced material usage directly translates to lower embodied energy and carbon footprint. Many lightweight materials are manufactured from recycled content or are themselves highly recyclable at the end of their service life.

| Environmental Factor | Traditional Concrete | Lightweight Concrete | Structural Steel | Engineered Wood |

|---|---|---|---|---|

| Embodied Energy (MJ/kg) | 1.2-1.5 | 0.8-1.1 | 35-40 | 2.5-3.5 |

| CO2 Emissions (kg/kg) | 0.12-0.15 | 0.08-0.12 | 2.5-3.0 | 0.3-0.4 |

| Recyclability | Limited | Limited | High | Moderate |

| Renewable Content | Low | Low to Moderate | Low | High |

Applications in Modern Construction

Residential and Commercial Buildings

Lightweight construction materials have found extensive applications in both residential and commercial building sectors. In residential construction, lightweight materials are used for wall systems, flooring, roofing, and insulation, contributing to energy-efficient and comfortable living environments. The speed of construction with lightweight systems is particularly advantageous in meeting housing demands in rapidly growing urban areas.

In commercial construction, lightweight materials enable innovative architectural designs, longer spans, and flexible interior spaces. They are particularly valuable in retrofitting existing structures where adding minimal weight is crucial. Lightweight curtain walls, partition systems, and raised floors are common applications that improve building performance while reducing structural loads.

Specialized and High-Performance Structures

Beyond conventional buildings, lightweight materials are essential in specialized structures such as long-span roofs, stadiums, airports, and temporary installations. Their high strength-to-weight ratio makes them ideal for structures where minimizing weight is critical for performance or economic reasons. Lightweight materials also play a crucial role in seismic design, as reduced mass results in lower earthquake forces.

Future Trends and Innovations

Advanced Material Development

The future of lightweight construction materials lies in the development of increasingly sophisticated composites and smart materials. Researchers are working on nanomaterials, aerogels, and bio-based composites that offer exceptional performance with minimal weight. These advanced materials may incorporate self-healing properties, phase-change materials for thermal management, or responsive characteristics that adapt to environmental conditions.

Digital Fabrication and Industry 4.0

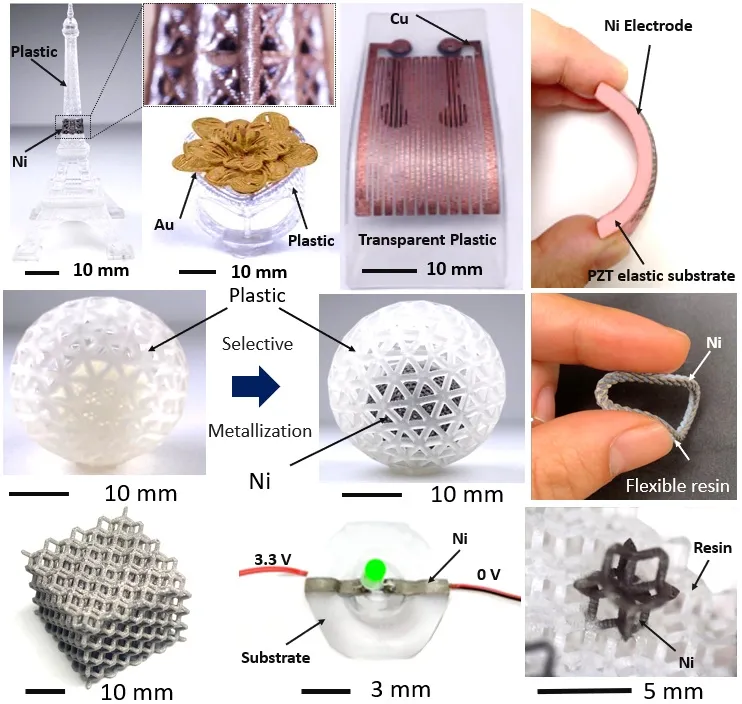

The integration of lightweight materials with digital fabrication technologies represents another significant trend. 3D printing, robotic assembly, and computer-aided manufacturing enable the production of complex, optimized structures that maximize performance while minimizing material usage. This digital approach allows for mass customization and unprecedented design freedom in architecture.

Sustainability and Circular Economy

Future developments in lightweight construction will increasingly focus on circular economy principles, with emphasis on recyclability, biodegradability, and closed-loop material cycles. Bio-based materials derived from agricultural waste, mycelium composites, and other renewable resources are gaining attention as sustainable alternatives to conventional lightweight materials.

Challenges and Considerations

Despite their numerous advantages, lightweight construction materials present certain challenges that must be addressed. These include higher initial costs for some advanced materials, limited familiarity among construction professionals, potential durability concerns in specific environments, and the need for specialized design approaches. Fire resistance, acoustic performance, and long-term behavior under various loading conditions require careful consideration in design and specification.

Regulatory frameworks and building codes are gradually adapting to accommodate lightweight construction systems, but inconsistencies and knowledge gaps still exist in some regions. Education and training for architects, engineers, and contractors are essential to maximize the benefits of these materials while ensuring safety and performance.

Conclusion

Lightweight construction materials represent a paradigm shift in building design and construction methodology. Their adoption supports the broader goals of sustainable development, resource efficiency, and resilience in the built environment. As material science continues to advance and construction practices evolve, lightweight materials will play an increasingly central role in creating buildings that are not only efficient and economical but also responsive to environmental challenges and user needs.

The ongoing research and innovation in this field promise even more sophisticated materials and systems in the future, potentially transforming how we conceive, design, and construct our built environment. The integration of lightweight principles with digital technologies, sustainable sourcing, and circular economy concepts points toward a future where buildings are lighter, smarter, and more in harmony with their environmental context.