Magnetic Alloys: Types, Properties and Applications

Introduction to Magnetic Alloys

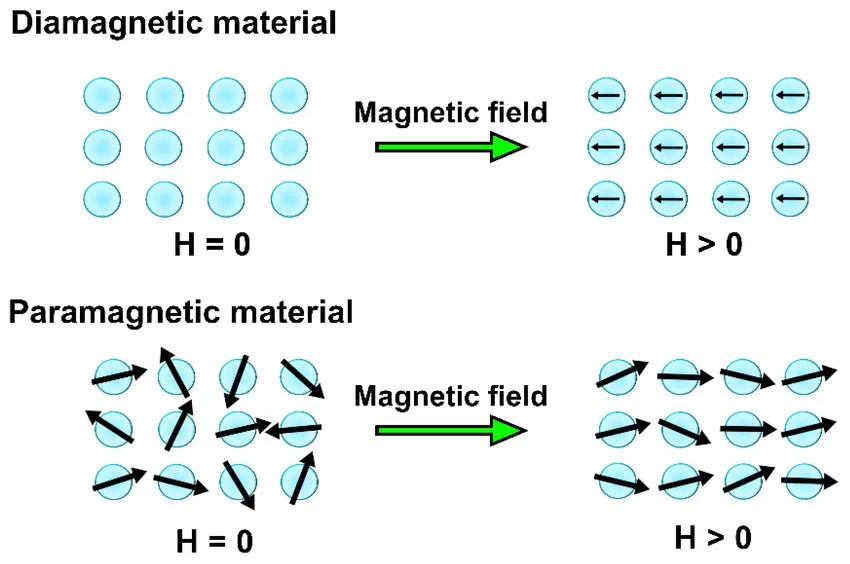

Magnetic alloys are specialized metallic compounds that exhibit magnetic properties, making them essential in numerous technological applications. These materials can be broadly categorized into ferromagnetic and ferrimagnetic substances, with their magnetic behavior stemming from the alignment of electron spins within their atomic structure. Understanding which alloys are magnetic and their specific properties is crucial for engineers, material scientists, and manufacturers working in fields ranging from electronics to renewable energy.

Atomic alignment patterns in ferromagnetic materials

Fundamental Types of Magnetic Alloys

Ferromagnetic Alloys

Ferromagnetic alloys are the most common type of magnetic materials and include iron, nickel, cobalt, and their alloys. These materials exhibit strong magnetic properties and can retain their magnetization even after the external magnetic field is removed. The strength of their magnetic properties depends on factors such as composition, crystal structure, and thermal history.

Soft Magnetic Alloys

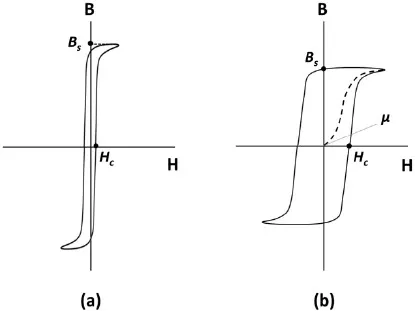

Soft magnetic alloys are characterized by their low coercivity, meaning they can be easily magnetized and demagnetized. These materials are ideal for applications requiring rapid magnetic field changes, such as transformers, electric motors, and magnetic shielding.

Hard Magnetic Alloys

Hard magnetic alloys, also known as permanent magnets, possess high coercivity and remanence, allowing them to maintain their magnetization over long periods. These materials are essential for applications where a constant magnetic field is required without continuous energy input.

Hysteresis loops comparing soft and hard magnetic materials

Common Magnetic Alloys and Their Properties

| Alloy Type | Main Components | Magnetic Properties | Common Applications |

|---|---|---|---|

| Carbon Steel | Iron, Carbon (0.2-2.1%) | Ferromagnetic, Moderate coercivity | Transformers, Electric motors |

| Alnico | Aluminum, Nickel, Cobalt, Iron | High remanence, Good temperature stability | Permanent magnets, Sensors |

| Silicon Steel | Iron, Silicon (1-4.5%) | Low hysteresis loss, High permeability | Transformer cores, Generators |

| Permalloy | Nickel (80%), Iron (20%) | Very high permeability, Low coercivity | Magnetic shielding, Recording heads |

| Neodymium Magnets | Neodymium, Iron, Boron | Extremely high magnetic strength | Hard disk drives, Electric vehicles |

Iron-Based Magnetic Alloys

Carbon Steels

Carbon steels are among the most widely used magnetic alloys due to their excellent magnetic properties and cost-effectiveness. The carbon content typically ranges from 0.2% to 2.1%, with higher carbon content generally improving hardness but potentially reducing magnetic permeability.

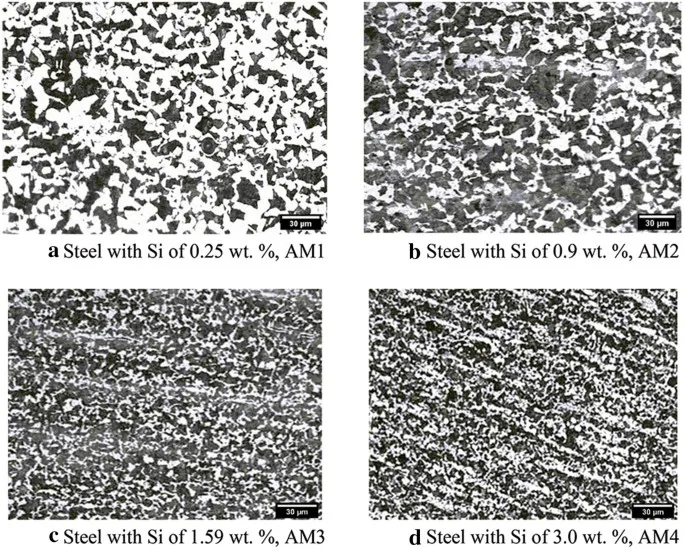

Silicon Steel (Electrical Steel)

Silicon steel, also known as electrical steel, contains 1-4.5% silicon, which increases electrical resistivity and reduces eddy current losses. This makes it ideal for applications in alternating current systems, particularly in transformer cores and electric motor laminations.

Microstructure of grain-oriented silicon steel

Nickel-Iron Alloys

Permalloy

Permalloy is a nickel-iron alloy with approximately 80% nickel and 20% iron. It exhibits extremely high magnetic permeability and low coercivity, making it ideal for sensitive magnetic applications. The specific composition can be adjusted to optimize properties for different applications.

Mu-metal

Mu-metal is a specialized nickel-iron alloy with additional elements such as copper and molybdenum. It possesses exceptionally high magnetic permeability at low field strengths, making it perfect for magnetic shielding applications where external magnetic fields must be excluded from sensitive equipment.

Cobalt-Based Alloys

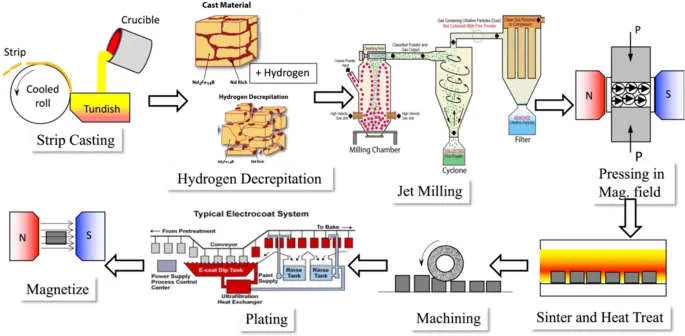

Alnico Alloys

Alnico alloys, composed primarily of aluminum, nickel, and cobalt with iron, were among the first widely used permanent magnet materials. They offer good temperature stability and relatively high magnetic energy products, though they have been largely superseded by rare-earth magnets in high-performance applications.

Cobalt-Samarium Alloys

Cobalt-samarium alloys represent an important class of permanent magnets with good temperature resistance and corrosion resistance. While not as strong as neodymium magnets, they maintain their magnetic properties at higher temperatures, making them suitable for specialized applications.

Casting process in alnico magnet production

Rare Earth Magnetic Alloys

Neodymium-Iron-Boron (NdFeB)

Neodymium magnets are the strongest commercially available permanent magnets, with energy products significantly higher than traditional magnetic materials. Their exceptional strength allows for miniaturization of electronic devices and improved efficiency in motors and generators.

Samarium-Cobalt (SmCo)

Samarium-cobalt magnets offer excellent temperature stability and corrosion resistance, though they are generally weaker than neodymium magnets. They are preferred in applications where performance must be maintained at elevated temperatures or in corrosive environments.

| Property | Neodymium Magnets | Samarium-Cobalt | Alnico | Ferrite |

|---|---|---|---|---|

| Maximum Energy Product (MGOe) | 35-52 | 16-32 | 5-9 | 3-5 |

| Coercivity (kOe) | 10-12 | 5-10 | 0.6-1.5 | 2-4 |

| Curie Temperature (°C) | 310-400 | 700-800 | 700-860 | 450-460 |

| Temperature Coefficient (%/°C) | -0.12 | -0.04 | -0.02 | -0.19 |

Factors Affecting Magnetic Properties

Composition and Crystal Structure

The magnetic properties of alloys are heavily influenced by their chemical composition and crystal structure. Elements such as chromium, manganese, and titanium can be added to modify magnetic characteristics, while heat treatment processes can optimize the microstructure for specific applications.

Grain Orientation

In many magnetic alloys, particularly electrical steels, controlling grain orientation is crucial for optimizing magnetic properties. Grain-oriented silicon steel, for example, has crystals aligned in a specific direction to maximize magnetic flux density along the rolling direction.

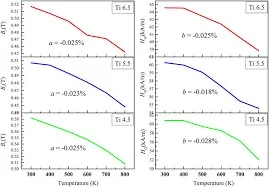

Temperature Effects

All magnetic materials lose their magnetic properties above a specific temperature known as the Curie point. Understanding the temperature dependence of magnetic properties is essential for designing systems that operate reliably across expected temperature ranges.

Temperature dependence of magnetic properties in various alloys

Applications of Magnetic Alloys

Electrical Power Generation and Distribution

Magnetic alloys are fundamental to electrical power systems, with silicon steel being the primary material for transformer cores and generator components. The efficiency of power conversion and transmission depends heavily on the magnetic properties of these materials.

Data Storage

From traditional hard disk drives to modern solid-state storage, magnetic alloys play a crucial role in data storage technologies. Thin films of magnetic materials are used to store digital information through controlled magnetization patterns.

Medical Applications

Magnetic alloys are essential in medical equipment such as MRI machines, where powerful magnetic fields are required for imaging. They are also used in various surgical instruments and implantable medical devices.

Future Trends in Magnetic Alloys

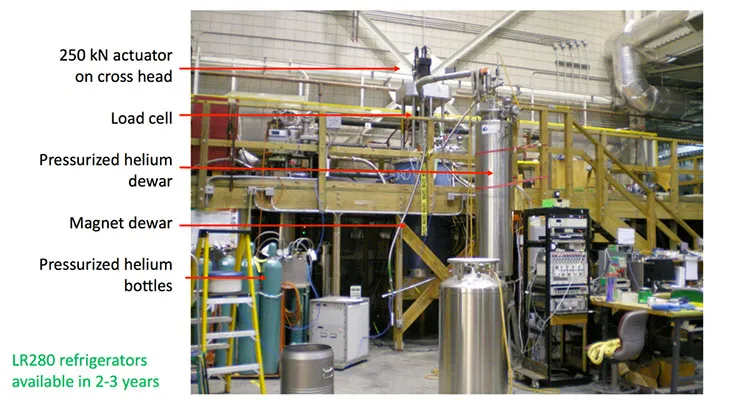

Advanced Manufacturing Techniques

Additive manufacturing and other advanced production methods are enabling the creation of magnetic components with complex geometries and optimized magnetic circuits that were previously impossible to manufacture.

Sustainable and Rare-Earth-Free Alternatives

Research is increasingly focused on developing magnetic materials that reduce or eliminate the need for rare-earth elements, addressing supply chain concerns and environmental impacts while maintaining performance.

Nanostructured Magnetic Materials

Nanotechnology is opening new possibilities for magnetic materials with enhanced properties, including exchange-spring magnets and materials with precisely controlled domain structures for improved efficiency.

Advanced laboratory for magnetic material development

Conclusion

Magnetic alloys represent a diverse and technologically critical class of materials with applications spanning virtually every sector of modern industry. From the common carbon steels to sophisticated rare-earth compounds, each magnetic alloy offers unique properties tailored to specific requirements. As technology continues to advance, the development of new magnetic materials with improved performance, sustainability, and manufacturability will remain a key focus of materials science and engineering research, driving innovation across multiple fields including energy, transportation, healthcare, and information technology.