Mechanical Properties of Polymer Materials

Polymer materials are ubiquitous in modern engineering and daily life, ranging from packaging and textiles to automotive components and medical devices. Their widespread use is largely due to their versatile mechanical properties, which can be tailored through chemical composition, processing techniques, and additives. Understanding these properties is crucial for selecting the right material for specific applications and predicting long-term performance.

Fundamental Mechanical Properties

The mechanical behavior of polymers is characterized by several key properties, including elasticity, strength, ductility, toughness, and viscoelasticity. Unlike metals and ceramics, polymers exhibit time-dependent and temperature-sensitive behavior due to their long-chain molecular structure.

Elastic Modulus and Stiffness

The elastic modulus (Young's modulus) measures a material's resistance to elastic deformation under stress. Polymers generally have lower moduli compared to metals and ceramics, making them more flexible. However, the modulus can vary significantly based on the polymer type:

- Elastomers (e.g., natural rubber): Very low modulus (0.01–0.1 GPa), highly elastic.

- Thermoplastics (e.g., polyethylene): Moderate modulus (0.2–4 GPa).

- Thermosets (e.g., epoxy): Higher modulus (2–10 GPa).

The stiffness of a polymer is influenced by factors such as chain rigidity, crystallinity, and cross-linking density. For instance, adding fillers like glass fibers can significantly increase the modulus.

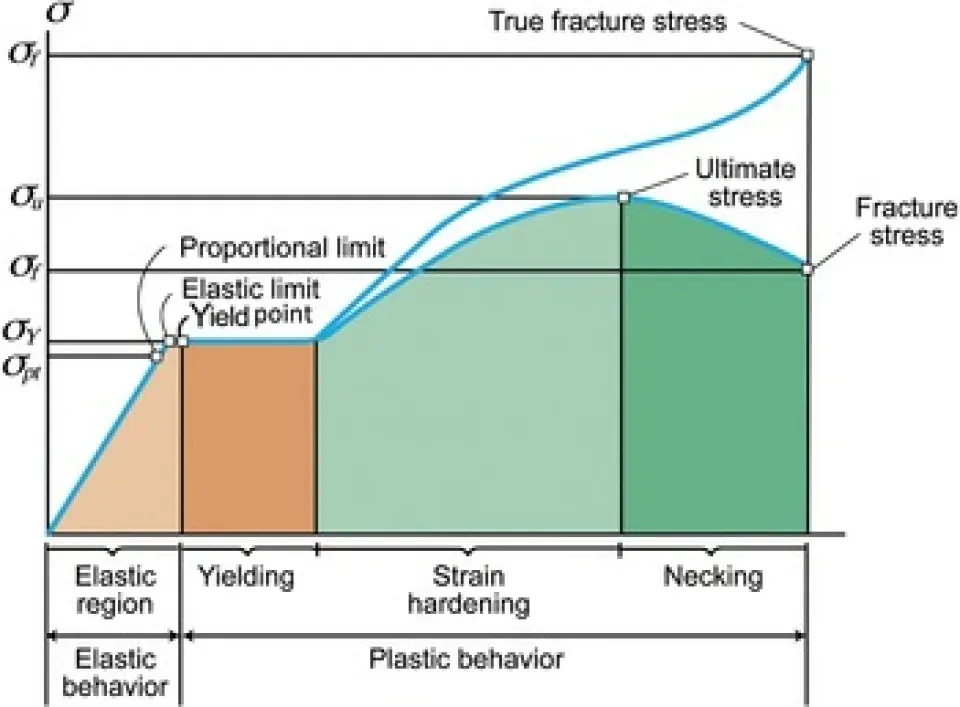

Tensile Strength and Yield Strength

Tensile strength is the maximum stress a material can withstand while being stretched before failure. Yield strength is the stress at which plastic deformation begins. Polymers like ultra-high-molecular-weight polyethylene (UHMWPE) can exhibit high tensile strength, while brittle polymers like polystyrene may fracture without yielding.

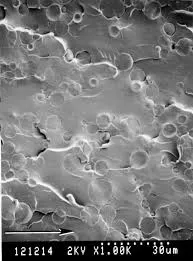

Ductility and Toughness

Ductility is the ability to deform plastically before fracture, often measured by elongation at break. Toughness, the energy absorbed before fracture, is the area under the stress-strain curve. Ductile polymers like polypropylene can undergo large deformations, while brittle polymers like PMMA fracture with little plastic deformation.

Viscoelastic Behavior

Polymers exhibit viscoelasticity, combining viscous (liquid-like) and elastic (solid-like) responses. This behavior leads to phenomena such as creep, stress relaxation, and strain rate dependence.

Creep and Stress Relaxation

Creep is the gradual deformation under constant load over time, critical for applications like pipes or load-bearing components. Stress relaxation is the decrease in stress under constant strain, important in seals and gaskets.

| Polymer | Max Service Temperature (°C) | Creep Modulus (GPa) at 1000 hours |

|---|---|---|

| Polyethylene (PE) | 60 | 0.2 |

| Polyvinyl Chloride (PVC) | 70 | 1.0 |

| Polycarbonate (PC) | 120 | 1.5 |

| Polytetrafluoroethylene (PTFE) | 260 | 0.1 |

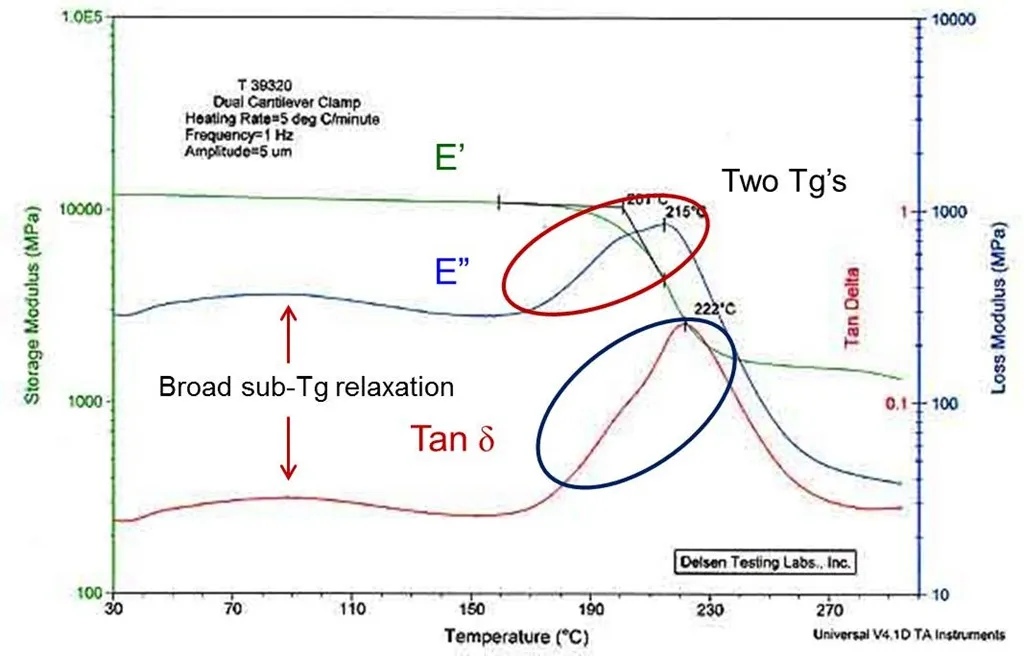

Dynamic Mechanical Analysis (DMA)

DMA is used to study viscoelastic properties by applying oscillatory stress and measuring strain response. It reveals the glass transition temperature (T g ), where polymers transition from glassy to rubbery states.

Factors Influencing Mechanical Properties

The mechanical performance of polymers is not intrinsic but depends on multiple factors:

Molecular Weight and Crystallinity

Higher molecular weight generally improves strength and toughness due to increased chain entanglement. Crystallinity enhances modulus, strength, and creep resistance but reduces ductility. Semi-crystalline polymers like nylon balance these properties.

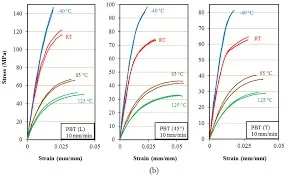

Temperature and Strain Rate

Mechanical properties are highly temperature-sensitive. Near T g , polymers become softer and more ductile. At high strain rates, behavior becomes more brittle due to reduced time for molecular relaxation.

Additives and Reinforcement

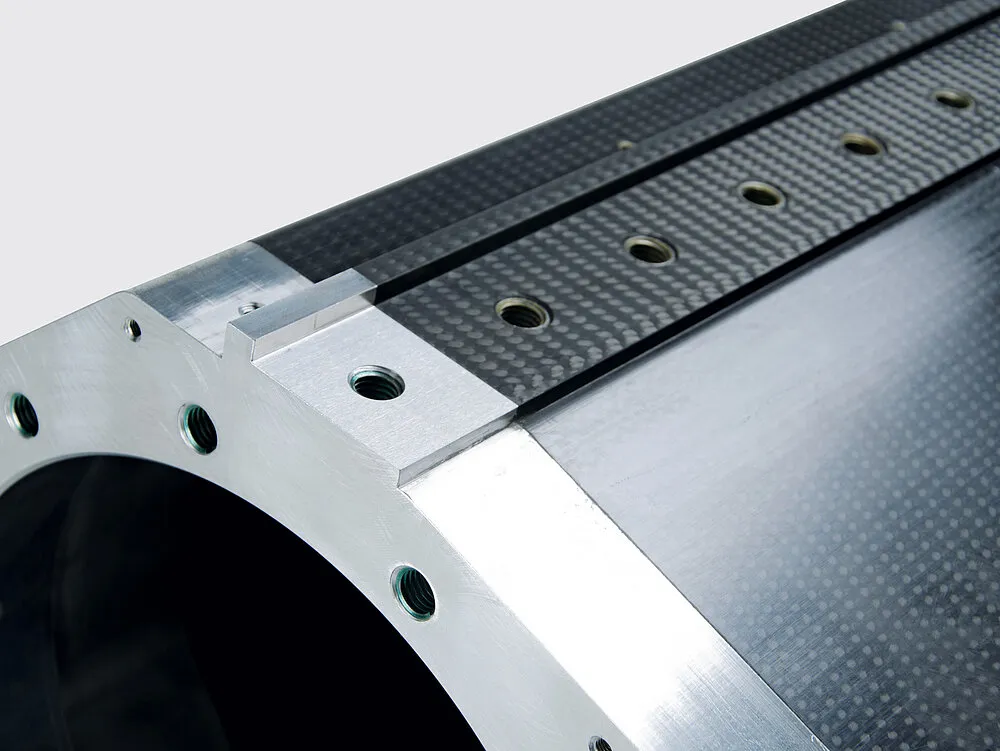

Additives like plasticizers increase ductility but reduce strength. Fillers (e.g., carbon black, silica) and reinforcements (e.g., glass, carbon fibers) significantly enhance modulus, strength, and thermal stability.

| Property | Unfilled Nylon 6 | Nylon 6 with 30% Glass Fiber |

|---|---|---|

| Tensile Strength (MPa) | 80 | 180 |

| Elastic Modulus (GPa) | 2.8 | 9.0 |

| Impact Strength (J/m) | 40 | 100 |

Applications and Material Selection

Understanding mechanical properties guides material selection:

- Flexible applications (e.g., hoses): Elastomers or plasticized PVC.

- Structural components (e.g., gears): Reinforced nylons or polycarbonates.

- High-temperature environments (e.g., engine parts): High-performance polymers like PEEK or polyimides.

Conclusion

The mechanical properties of polymer materials are complex and influenced by molecular structure, processing, and environmental conditions. Their versatility allows for customization through formulation and reinforcement, enabling diverse applications. Ongoing research focuses on developing polymers with enhanced mechanical performance, sustainability, and multifunctionality to meet future engineering challenges.