Multifunctional Conductive Composite Materials for Aerospace and Defense

The aerospace and defense industries are perpetually at the forefront of technological innovation, demanding materials that offer not just structural integrity but a suite of advanced functionalities. Multifunctional conductive composite materials have emerged as a transformative class of materials, engineered to provide a unique combination of electrical conductivity, electromagnetic interference (EMI) shielding, structural strength, thermal management, and even sensing capabilities. These materials are pivotal in developing next-generation aircraft, satellites, unmanned aerial vehicles (UAVs), and military equipment, enabling lighter, smarter, and more efficient systems.

Core Composition and Functionality

At their heart, multifunctional conductive composites are typically polymer matrix composites (PMCs) reinforced with conductive fillers. The polymer matrix, often an epoxy, polyimide, or thermoplastic, provides the foundational structure, chemical resistance, and lightweight properties. The multifunctionality is primarily imparted by the incorporation of conductive nanoscale or microscale fillers. These include:

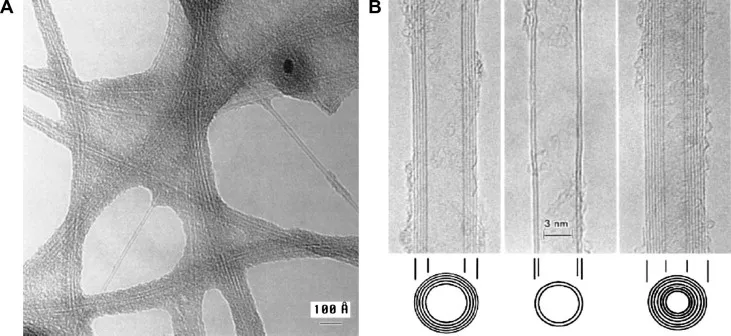

- Carbon-Based Materials: Carbon nanotubes (CNTs), graphene nanoplatelets, and carbon fibers are among the most common. They offer an exceptional balance of high electrical and thermal conductivity alongside remarkable mechanical strength.

- Metallic Nanoparticles: Silver, copper, and nickel nanoparticles are used to create highly conductive percolation networks within the polymer matrix.

- Conductive Polymers: Intrinsically conductive polymers like PEDOT:PSS can be blended with traditional polymers to add functionality without relying solely on particulate fillers.

The synergy between these components results in a material that is far greater than the sum of its parts.

Key Applications in Aerospace and Defense

1. Lightning Strike Protection

Traditional aircraft are highly susceptible to lightning strikes, which can cause severe damage to non-conductive composite structures like carbon fiber reinforced polymer (CFRP) wings and fuselages. Multifunctional composites with integrated conductive layers, often containing copper or aluminum meshes or non-woven veils of carbon nanotubes, provide a path for the immense electrical current to safely dissipate, preventing structural damage and protecting onboard electronics.

2. Electromagnetic Interference (EMI) Shielding

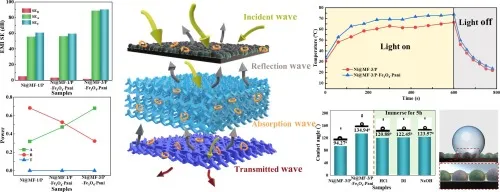

The dense concentration of avionics, radar, and communication systems in modern platforms creates a complex electromagnetic environment. EMI can disrupt critical systems, leading to malfunctions. Conductive composites act as effective shields, reflecting and absorbing electromagnetic radiation. This eliminates the need for secondary shielding treatments, reducing weight and complexity.

3. Structural Health Monitoring (SHM)

The ability to self-monitor for damage is a revolutionary application. By embedding networks of conductive nanomaterials (e.g., CNTs) or optical fibers within a composite structure, the material itself can sense strain, cracks, or delaminations. Changes in electrical resistance or signal transmission can be measured and analyzed to assess structural integrity in real-time, enabling predictive maintenance and enhancing safety.

4. De-Icing and Thermal Management

Ice accumulation on wings and engine inlets is a major aviation hazard. Conductive composites can be used to create integrated heating elements. By applying an electrical current, the material Joule-heats, efficiently melting ice without the need for bleed air from engines or separate weeping wing systems, thereby improving efficiency. Similarly, these materials can manage heat distribution in high-power electronic systems on satellites.

Comparative Advantages Over Traditional Materials

| Feature | Traditional Materials (e.g., Aluminum) | Multifunctional Conductive Composites |

|---|---|---|

| Weight | Higher density | Significantly lighter |

| Corrosion Resistance | Prone to corrosion | Highly resistant |

| Functionality | Primarily structural | Structural + Conductive + Sensing |

| Manufacturing Complexity | Simpler assembly | Integrated functions reduce part count |

| Radar Cross-Section | High reflectivity | Tunable absorption for stealth |

Challenges and Future Directions

Despite their promise, the widespread adoption of these materials faces hurdles. Achieving a uniform dispersion of nanofillers to avoid agglomeration is a significant manufacturing challenge. The long-term durability and performance under extreme environmental conditions (e.g., UV exposure, temperature cycles) require further validation. Furthermore, the cost of nanomaterials like CNTs and graphene, though decreasing, remains a factor for large-scale production.

Future research is focused on developing more scalable and cost-effective manufacturing processes, such as automated fiber placement with integrated functionality. There is also a growing interest in creating bio-inspired and self-healing conductive composites that can autonomously repair minor damage, further extending the lifespan and reliability of aerospace and defense systems.

Conclusion

Multifunctional conductive composite materials represent a paradigm shift in material science for aerospace and defense. By integrating electrical conductivity, sensing, and thermal management into structural components, they enable unprecedented levels of performance, efficiency, and safety. As research overcomes current challenges related to manufacturing and cost, these intelligent materials are poised to become the standard, forming the backbone of the next generation of aircraft, spacecraft, and military technology, ensuring lighter, more connected, and more resilient platforms.