Multifunctional Phase-change Energy Storage Materials for Smart Textiles and Wearable Devices

Introduction to Phase-change Materials in Textile Applications

Phase-change materials (PCMs) represent a groundbreaking class of substances that can store, release, and manage thermal energy through phase transitions, typically between solid and liquid states. These materials have emerged as crucial components in the development of advanced smart textiles and wearable devices, offering unprecedented capabilities in thermal regulation, energy storage, and multifunctional performance. The integration of PCMs into textile structures has opened new frontiers in personal comfort, healthcare monitoring, and energy-efficient wearable technology.

Fundamental Principles of Phase-change Energy Storage

Thermal Energy Storage Mechanism

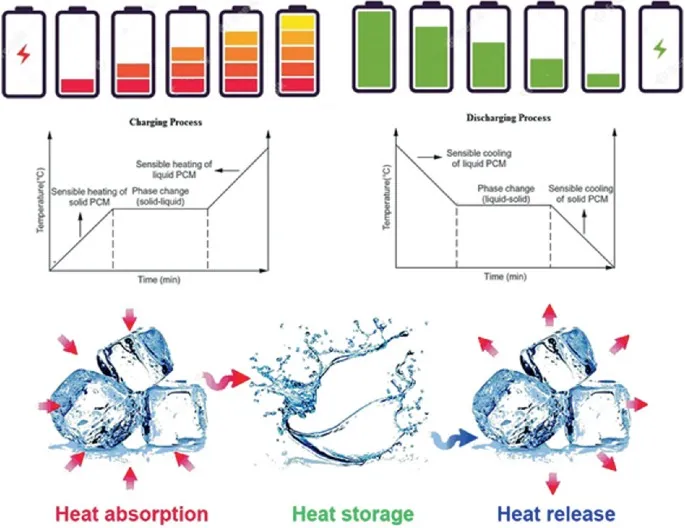

PCMs operate on the principle of latent heat storage, where energy is absorbed or released during phase transitions without significant temperature changes. When the ambient temperature rises above the PCM's melting point, the material absorbs heat as it changes from solid to liquid. Conversely, when temperatures drop below the freezing point, the PCM releases stored heat as it solidifies. This unique property enables precise temperature control within a narrow range, making PCMs ideal for maintaining thermal comfort in wearable applications.

Key Thermal Properties

The effectiveness of PCMs in textile applications depends on several critical thermal properties:

| Property | Description | Importance in Textiles |

|---|---|---|

| Phase Change Temperature | Temperature at which phase transition occurs | Determines comfort range for human body |

| Latent Heat Capacity | Amount of energy stored per unit mass | Defines duration of thermal regulation |

| Thermal Conductivity | Rate of heat transfer through material | Affects response time to temperature changes |

| Cycling Stability | Ability to maintain performance over multiple cycles | Ensures long-term durability of smart textiles |

Types of Phase-change Materials for Textile Integration

Organic PCMs

Organic PCMs, including paraffins and fatty acids, offer excellent thermal stability, non-corrosiveness, and consistent performance over numerous phase-change cycles. Paraffin-based PCMs are particularly popular in textile applications due to their wide range of phase-change temperatures and high latent heat storage capacity. These materials can be microencapsulated and integrated into fibers, coatings, or foams for textile applications.

Inorganic PCMs

Inorganic PCMs, such as salt hydrates and metallic alloys, typically exhibit higher thermal conductivity and greater volumetric energy storage density compared to organic alternatives. However, challenges like supercooling and phase separation have limited their widespread adoption in textile applications. Recent advancements in nano-encapsulation techniques are addressing these limitations and expanding their potential uses.

Bio-based PCMs

Emerging bio-based PCMs derived from natural sources offer sustainable alternatives with reduced environmental impact. These materials, including plant-derived fatty acids and biopolyols, provide comparable thermal performance while addressing growing concerns about sustainability and biodegradability in textile manufacturing.

Integration Methods in Smart Textiles

Microencapsulation Technology

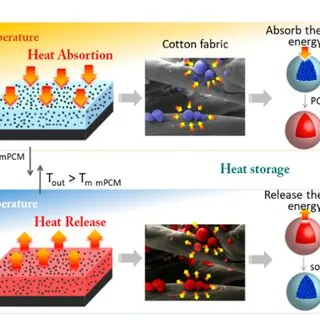

Microencapsulation represents the most widely adopted method for incorporating PCMs into textiles. This technique involves enclosing PCM particles within protective polymer shells, typically ranging from 1 to 100 micrometers in diameter. The microcapsules can then be integrated into fibers during spinning, applied as coatings, or incorporated into textile finishes. This approach prevents PCM leakage during phase transitions and maintains textile flexibility and handle.

Fiber Modification Techniques

Advanced fiber modification methods enable direct incorporation of PCMs into synthetic and natural fibers. Techniques such as hollow fiber filling, coaxial spinning, and surface modification allow for higher PCM loading capacities and improved thermal performance. These methods ensure uniform distribution of PCM throughout the textile structure, enhancing overall thermal regulation efficiency.

Composite Fabric Structures

Multilayer composite fabrics incorporating PCM-containing layers offer sophisticated thermal management solutions. These structures often combine PCM layers with other functional materials, creating smart textiles capable of adaptive thermal regulation, moisture management, and additional smart functionalities.

Applications in Wearable Devices and Smart Textiles

Thermal Comfort Management

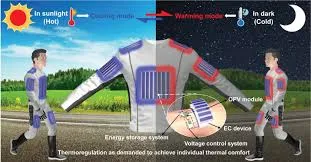

PCM-integrated textiles provide dynamic thermal regulation in clothing for various environments and activities. From outdoor sports apparel that maintains optimal body temperature during exertion to protective clothing for extreme temperature conditions, PCMs enhance wearer comfort and safety. The temperature-buffering effect reduces thermal stress and improves overall wearing experience.

Medical and Healthcare Applications

In healthcare settings, PCM-based textiles find applications in therapeutic garments, wound dressings, and temperature management systems for patients with thermal regulation disorders. Smart bandages incorporating PCMs can maintain optimal wound temperature, promoting faster healing while monitoring healing progress through integrated sensors.

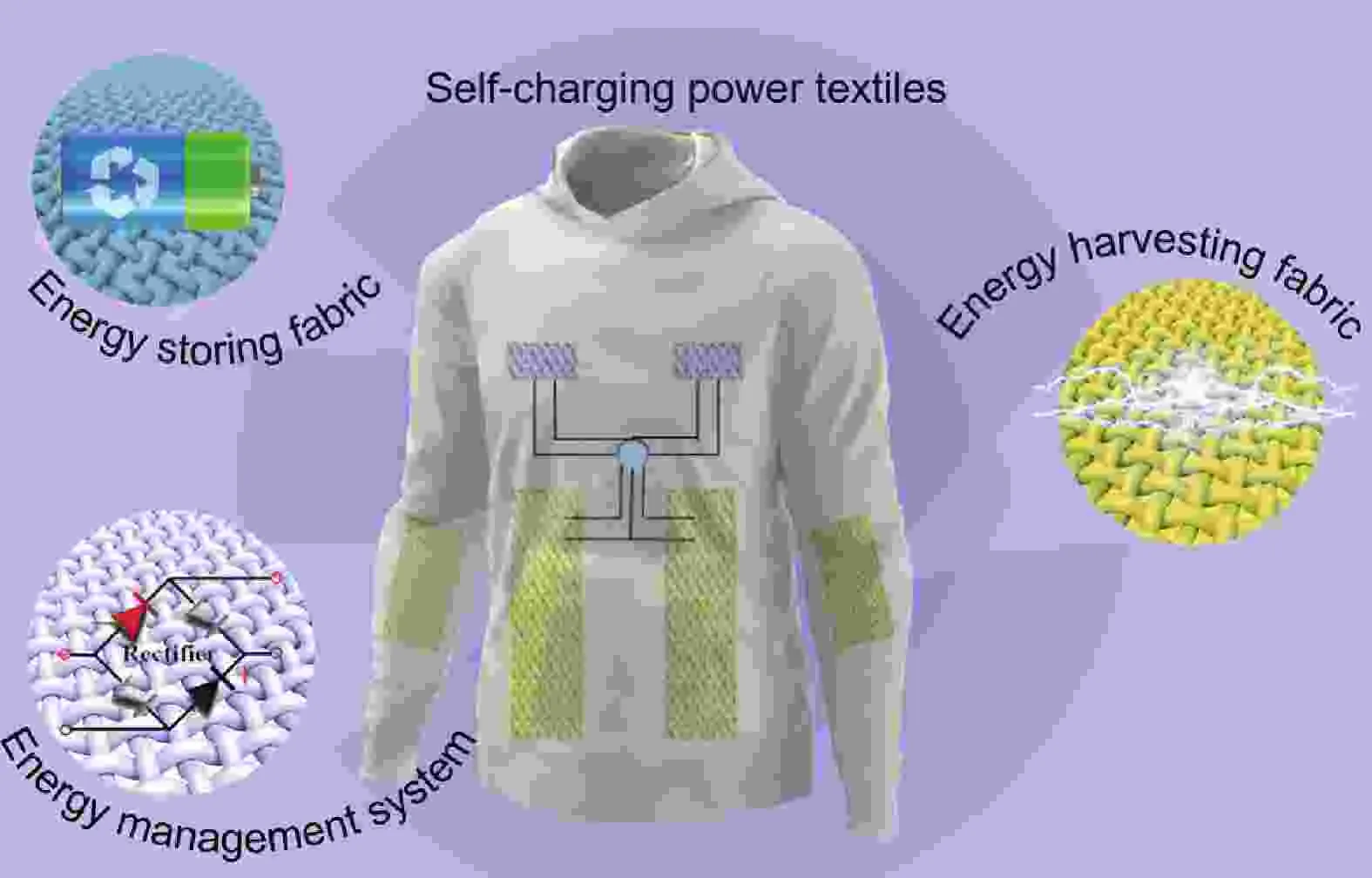

Energy Harvesting and Storage

Advanced PCM systems in wearable devices can harvest and store thermal energy from body heat or environmental sources. This capability enables self-powering mechanisms for low-energy wearable electronics, reducing dependency on external power sources and extending device operational time.

Interactive Smart Textiles

Combining PCMs with other smart materials creates interactive textiles that respond to environmental stimuli. These systems can incorporate shape memory alloys, conductive polymers, and sensing elements to create adaptive clothing that modifies its properties based on temperature changes, user activity, or environmental conditions.

Performance Characteristics and Evaluation

| Performance Metric | Testing Method | Industry Standard | Typical Values |

|---|---|---|---|

| Thermal Regulation Capacity | Differential Scanning Calorimetry (DSC) | ASTM F2370 | 5-15 J/g |

| Durability | Multiple Washing Cycles | AATCC 135 | 20-50 cycles |

| Comfort Parameters | Thermal Manikin Testing | ISO 15831 | 0.05-0.15 m²K/W |

| Energy Storage Efficiency | Thermal Cycling Analysis | ISO 11357 | 80-95% |

Challenges and Future Perspectives

Technical Challenges

Despite significant advancements, several challenges remain in the widespread adoption of PCM-based smart textiles. These include limited PCM loading capacity in textiles, reduced thermal conductivity affecting response times, durability issues during laundering, and cost considerations for mass production. Ongoing research focuses on developing nano-enhanced PCMs, improved encapsulation techniques, and multifunctional composite materials to address these limitations.

Sustainability Considerations

The environmental impact of PCM production, integration processes, and end-of-life disposal requires careful consideration. Future developments must prioritize biodegradable encapsulation materials, renewable PCM sources, and circular economy principles to ensure sustainable advancement of PCM technology in textiles.

Emerging Research Directions

Cutting-edge research explores the integration of PCMs with other advanced technologies, including flexible electronics, Internet of Things (IoT) connectivity, and artificial intelligence. These developments promise to create truly intelligent textile systems capable of autonomous thermal management, health monitoring, and adaptive functionality based on user needs and environmental conditions.

Conclusion

Multifunctional phase-change energy storage materials represent a transformative technology in the evolution of smart textiles and wearable devices. Their ability to provide dynamic thermal regulation, energy storage, and multifunctional performance positions them as key enablers for next-generation wearable technology. As research continues to address existing challenges and explore new applications, PCM-integrated textiles are poised to revolutionize personal comfort, healthcare monitoring, and sustainable energy solutions in wearable technology. The convergence of materials science, textile engineering, and electronics will undoubtedly unlock new possibilities for intelligent, responsive, and energy-efficient wearable systems that seamlessly integrate with human activities and environmental needs.