Polymer Materials: Structure, Properties, and Applications

Polymer materials represent one of the most versatile and widely used classes of materials in modern technology. These macromolecular compounds, composed of repeating structural units, have revolutionized numerous industries from packaging and textiles to biomedical engineering and electronics. The term "polymer" derives from the Greek words "poly" (many) and "meros" (parts), reflecting their molecular structure consisting of many repeating units connected by covalent chemical bonds.

The development of polymer science began in the early 20th century, but natural polymers like cellulose, rubber, and proteins have been used by humans for centuries. The advent of synthetic polymers like Bakelite in 1907 marked the beginning of the polymer age, which expanded dramatically with the development of polyethylene, polypropylene, nylon, and other synthetic materials that now permeate every aspect of modern life.

Classification of Polymer Materials

Polymers can be classified based on various criteria including origin, structure, thermal behavior, and application. Understanding these classifications is essential for selecting the appropriate material for specific applications.

Based on Origin

Polymers are primarily categorized as natural, synthetic, or semi-synthetic:

- Natural polymers: These occur in nature and include proteins, nucleic acids, cellulose, natural rubber, and silk.

- Synthetic polymers: Human-made polymers produced through chemical synthesis, including polyethylene, polyvinyl chloride (PVC), nylon, and Teflon.

- Semi-synthetic polymers: Chemically modified natural polymers such as vulcanized rubber, cellulose acetate, and nitrocellulose.

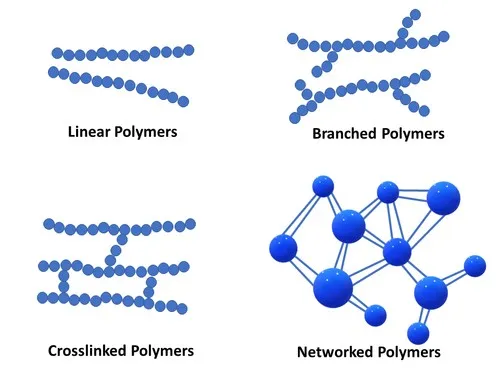

Based on Molecular Structure

The arrangement of polymer chains significantly influences material properties:

- Linear polymers: Chains arranged in long straight lines, often forming crystalline regions (e.g., high-density polyethylene).

- Branched polymers: Side chains connected to main chains, reducing packing efficiency and crystallinity (e.g., low-density polyethylene).

- Cross-linked polymers: Chains connected by covalent bonds, creating network structures (e.g., vulcanized rubber, epoxy resins).

Based on Thermal Behavior

Polymers respond differently to heat, leading to two primary categories:

- Thermoplastics: Soften when heated and harden when cooled, allowing for recycling and reshaping (e.g., polyethylene, polypropylene).

- Thermosets: Undergo irreversible curing process, forming cross-linked networks that don't melt upon heating (e.g., epoxy resins, phenolic resins).

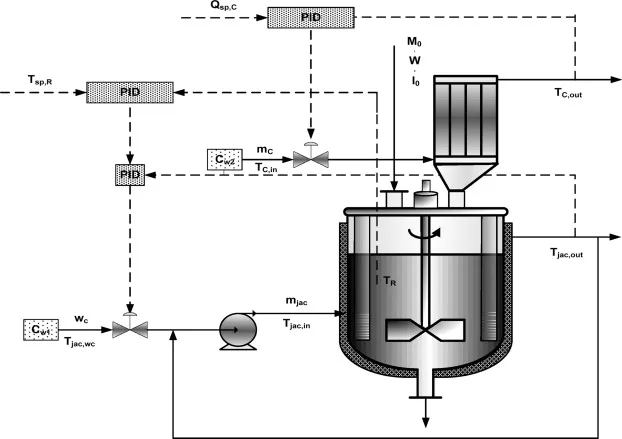

Polymer Synthesis Methods

The production of polymers involves various polymerization techniques, each yielding materials with distinct characteristics.

Addition Polymerization

Also known as chain-growth polymerization, this process involves the sequential addition of monomer units to a growing chain. Common techniques include:

- Free radical polymerization

- Ionic polymerization (cationic and anionic)

- Coordination polymerization (Ziegler-Natta catalysis)

Condensation Polymerization

Step-growth polymerization where monomers join together, releasing small molecules like water or methanol as byproducts. This method produces polymers like polyesters, polyamides, and polycarbonates.

Properties of Polymer Materials

The properties of polymers make them suitable for diverse applications:

| Property | Description | Example Polymers |

|---|---|---|

| Mechanical Strength | Ability to withstand applied forces | Kevlar, Ultra-high-molecular-weight polyethylene |

| Thermal Stability | Resistance to decomposition at high temperatures | Polyimides, Polytetrafluoroethylene (PTFE) |

| Chemical Resistance | Inertness to chemicals and solvents | PTFE, Polypropylene, PVC |

| Electrical Insulation | Resistance to electric current | Polyethylene, Polyvinyl chloride |

| Optical Clarity | Transparency to light | Polycarbonate, Polymethyl methacrylate |

Applications of Polymer Materials

Polymers have found applications in virtually every sector of modern society:

Packaging Industry

Polymers dominate the packaging sector due to their lightweight, durability, and barrier properties. Common packaging polymers include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polyvinyl chloride (PVC).

Medical and Healthcare

Biocompatible polymers have revolutionized healthcare through applications including:

- Implants and prosthetics (silicones, polyethylene joints)

- Drug delivery systems (biodegradable polyesters)

- Medical devices and equipment

- Packaging for pharmaceuticals and medical instruments

Automotive and Aerospace

The transportation industry utilizes polymers to reduce weight, improve fuel efficiency, and enhance design flexibility. Applications include interior components, exterior body parts, seals, gaskets, and composite materials for structural applications.

Electronics and Electrical

Polymers serve as insulators, encapsulants, and structural components in electronic devices. Conductive polymers have opened new possibilities for flexible electronics, displays, and sensors.

Advanced Polymer Materials

Recent developments have led to sophisticated polymer materials with enhanced properties:

Biodegradable Polymers

Environmentally friendly polymers designed to break down after use, including polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers.

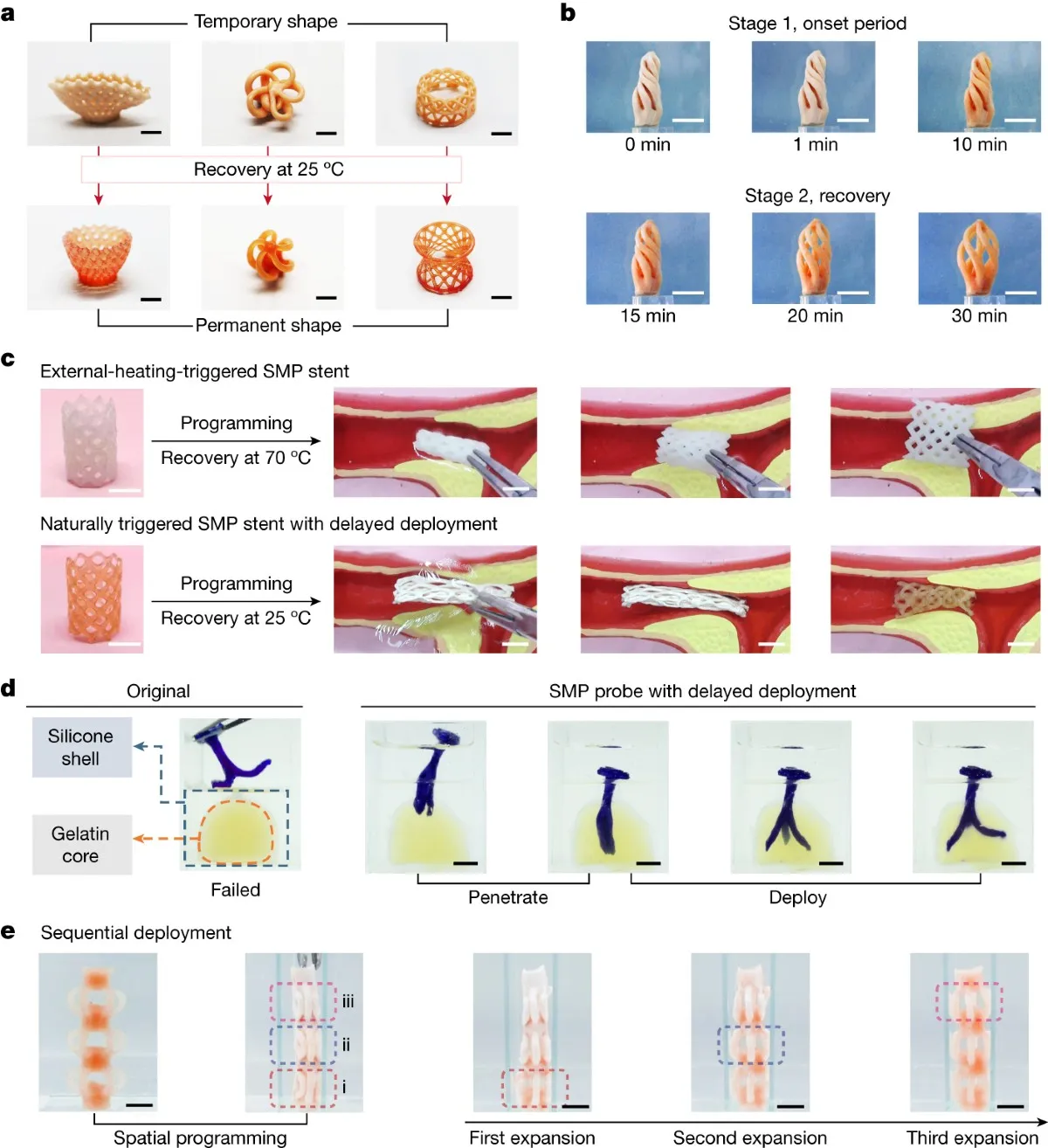

Smart and Responsive Polymers

Polymers that respond to external stimuli such as temperature, pH, light, or electric fields, enabling applications in drug delivery, sensors, and actuators.

Polymer Nanocomposites

Polymers reinforced with nanoscale fillers (e.g., carbon nanotubes, graphene, nanoclay) that significantly enhance mechanical, thermal, and barrier properties.

Environmental Considerations and Sustainability

The widespread use of polymers, particularly single-use plastics, has raised significant environmental concerns. Addressing these challenges involves:

- Developing biodegradable and compostable polymers

- Improving recycling technologies and infrastructure

- Implementing circular economy approaches

- Exploring bio-based feedstocks for polymer production

Future Trends in Polymer Materials

The field of polymer science continues to evolve with several promising directions:

- Self-healing polymers: Materials capable of autonomously repairing damage

- Polymers for energy applications: Including batteries, fuel cells, and solar cells

- 4D printing: Additive manufacturing of objects that change shape over time

- Sustainable polymer production: Green chemistry approaches and bio-based monomers

Conclusion

Polymer materials have transformed modern society and continue to enable technological advancements across diverse fields. As we address environmental challenges and develop increasingly sophisticated materials, polymers will remain at the forefront of materials science and engineering. The future of polymer materials lies in developing sustainable, multifunctional, and intelligent materials that meet the evolving needs of society while minimizing environmental impact.

Polymer materials are essential in modern technology, offering versatility and unique properties. This article explores their classification, synthesis methods, applications, and future trends, highlighting their impact across industries.