The Future of Packaging: Embracing Biodegradable Materials

The global packaging industry is undergoing a significant transformation, driven by increasing environmental awareness and consumer demand for sustainable solutions. Traditional plastic packaging, derived from fossil fuels, poses a severe threat to ecosystems due to its persistence in the environment for centuries. In response, biodegradable materials have emerged as a promising alternative, offering the functionality of conventional packaging without the long-term environmental burden. These materials are designed to break down naturally into harmless substances like water, carbon dioxide, and biomass through the action of microorganisms, completing a natural cycle and reducing landfill waste.

What Are Biodegradable Packaging Materials?

Biodegradable packaging refers to materials that can be decomposed by living organisms, primarily microbes, under appropriate conditions of moisture, oxygen, and temperature. It is crucial to distinguish between "biodegradable" and "compostable." While all compostable materials are biodegradable, not all biodegradable materials are compostable. Compostable materials break down within a specific timeframe in a composting environment, leaving no toxic residue and producing nutrient-rich compost.

Key Types of Biodegradable Materials

Several innovative materials are leading the charge in sustainable packaging:

- Polylactic Acid (PLA): A bioplastic derived from fermented plant starch (usually corn). It is transparent and rigid, making it a popular choice for containers, bottles, and films.

- Starch-Based Blends: Packaging made from potato, corn, or wheat starch. These often resemble traditional foam packaging but are fully compostable.

- Molded Pulp: Typically made from recycled paperboard or newsprint, it is widely used for protective packaging for eggs, fruits, and electronics.

- Polyhydroxyalkanoates (PHA): Produced by microorganisms that consume plant sugars, PHA is a versatile and marine-degradable bioplastic.

- Chitosan: Derived from the shells of crustaceans, this material shows great promise for flexible packaging and coatings.

Environmental Benefits and Advantages

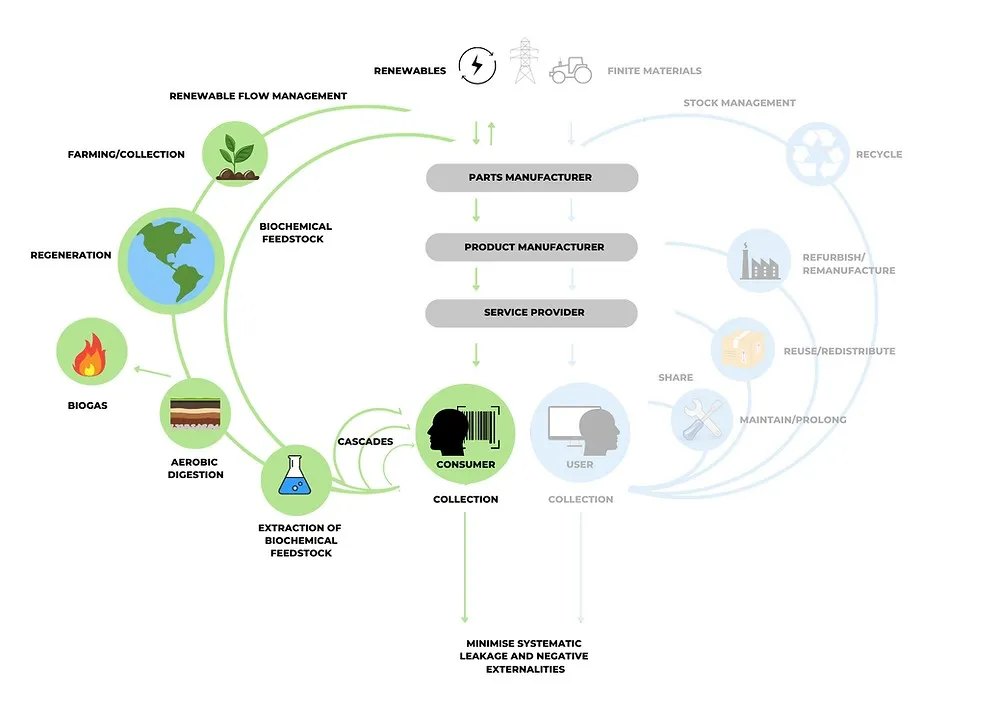

The shift to biodegradable packaging offers a multitude of ecological advantages, fundamentally changing the product lifecycle from a linear "take-make-dispose" model to a more circular one.

Reduction in Plastic Pollution

The most immediate benefit is the drastic reduction in plastic waste that clogs oceans and harms wildlife. Biodegradable materials break down much faster, minimizing their impact if they accidentally end up in natural environments.

Lower Carbon Footprint

Most biodegradable materials are sourced from renewable biomass. The plants used for feedstocks absorb carbon dioxide as they grow, which can offset the emissions from production, leading to a lower overall carbon footprint compared to petroleum-based plastics.

Waste Diversion and Composting

These materials can be processed in industrial composting facilities, turning waste into valuable compost that enriches soil, reduces the need for chemical fertilizers, and closes the nutrient loop. This diverts significant waste volume from landfills.

Challenges and Considerations

Despite their promise, the widespread adoption of biodegradable packaging faces several hurdles that need to be addressed.

| Material Type | Source | Biodegradation Time* | Key Challenge |

|---|---|---|---|

| Conventional Plastic (PET) | Fossil Fuels | 450+ years | Persistence in environment, microplastics |

| Polylactic Acid (PLA) | Corn Starch | 3-6 months (industrial compost) | Requires specific composting conditions |

| Molded Pulp | Recycled Paper | 2-3 months | Limited barrier properties |

| Starch-Based Blends | Potato/Corn Starch | 2-5 months | Can be sensitive to moisture |

| *Time can vary significantly based on environmental conditions. | |||

Infrastructure and Labeling

Proper disposal is critical. Many biodegradable materials require the high temperatures of an industrial composting facility to break down efficiently. A lack of consumer awareness and access to such facilities can lead to contamination in recycling streams or materials being sent to landfills where they may not degrade optimally.

Performance and Cost

While rapidly improving, some biodegradable materials may have limitations in durability, barrier properties (against oxygen or moisture), or heat resistance compared to conventional plastics. Furthermore, production costs are often higher, though they are expected to decrease with technological advancements and economies of scale.

The Path Forward: Innovation and Responsibility

The future of biodegradable packaging hinges on continued innovation, supportive policies, and corporate responsibility. Research is focused on improving material performance, developing home-compostable options, and creating materials from non-food biomass like agricultural waste. Governments can play a role by incentivizing sustainable packaging and funding waste management infrastructure. Ultimately, brands and consumers must work together to ensure these materials are used and disposed of correctly, fulfilling their promise of a cleaner planet.