Thermal Conductivity Modulation in Microencapsulated Phase-change Energy Storage Materials

Introduction to Microencapsulated Phase-change Materials

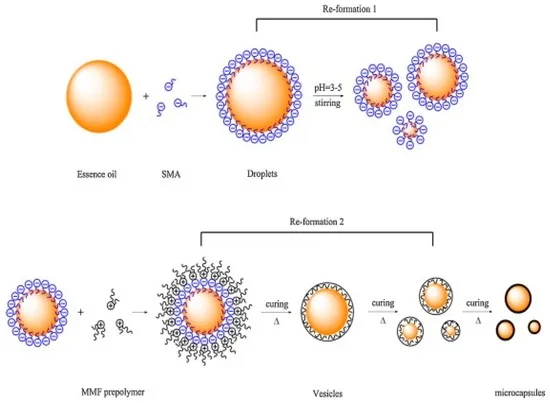

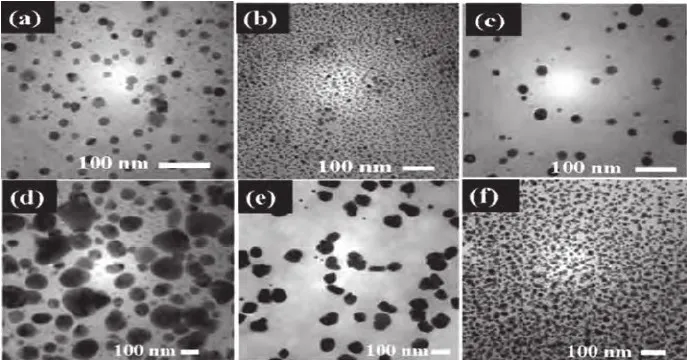

Microencapsulated phase-change materials (MPCMs) represent a significant advancement in thermal energy storage technology, offering enhanced stability, controlled phase transitions, and improved heat transfer characteristics. These materials consist of phase-change core substances encapsulated within protective shells, typically ranging from 1 to 1000 micrometers in diameter. The encapsulation process not only prevents leakage during phase transitions but also provides a stable framework for thermal conductivity enhancement.

Fundamental Challenges in Thermal Conductivity

The primary limitation of conventional phase-change materials lies in their inherently low thermal conductivity, which typically ranges between 0.1 and 0.3 W/m·K for organic PCMs. This thermal resistance significantly impedes heat transfer rates during charging and discharging cycles, limiting the practical application of MPCMs in high-power thermal management systems. The thermal conductivity challenge becomes particularly pronounced in microencapsulated systems where additional interfacial thermal resistance between the core and shell materials further complicates heat transfer mechanisms.

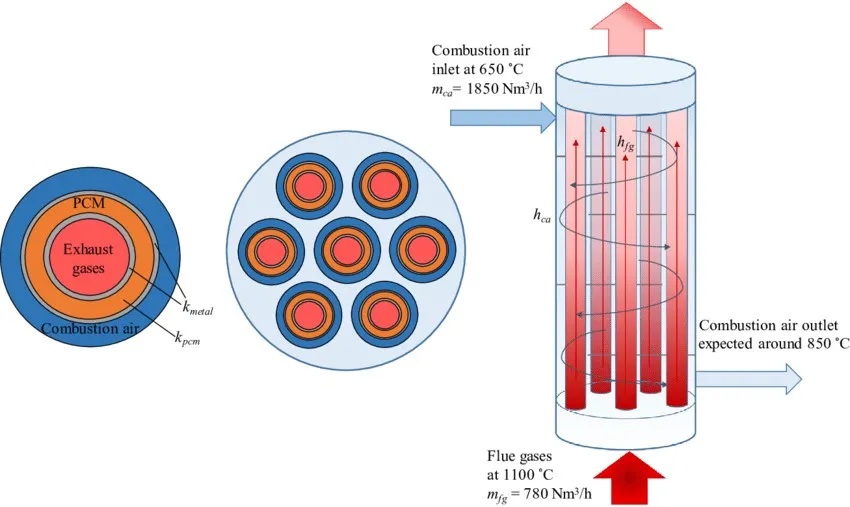

Thermal Transport Mechanisms in MPCMs

Heat transfer in MPCMs occurs through multiple parallel pathways: conduction through the PCM core, conduction through the shell material, and interfacial thermal transport at the core-shell boundary. The overall effective thermal conductivity depends on the relative contributions of these pathways and their respective thermal resistances. Understanding these mechanisms is crucial for developing effective enhancement strategies.

Advanced Enhancement Strategies

Nanoparticle Incorporation

The dispersion of high-thermal-conductivity nanoparticles within the PCM core represents one of the most effective approaches for thermal conductivity modulation. Metallic nanoparticles (copper, silver, aluminum), carbon-based nanomaterials (graphene, carbon nanotubes), and ceramic nanoparticles (aluminum oxide, boron nitride) have demonstrated significant improvements in thermal transport properties.

| Nanoparticle Type | Concentration (wt%) | Thermal Conductivity Improvement | Application Temperature Range |

|---|---|---|---|

| Graphene nanoplatelets | 1-5% | 150-400% | -20°C to 150°C |

| Carbon nanotubes | 0.5-3% | 120-350% | -50°C to 200°C |

| Silver nanoparticles | 2-8% | 200-500% | 0°C to 300°C |

| Aluminum oxide | 3-10% | 80-250% | -50°C to 400°C |

Shell Material Optimization

The selection and modification of shell materials play a critical role in thermal conductivity enhancement. Traditional polymer shells, while providing excellent mechanical stability and encapsulation efficiency, typically exhibit low thermal conductivity. Recent research has focused on developing composite shells incorporating thermally conductive fillers or transitioning to ceramic and metallic shell materials where application requirements permit.

Structural Design Innovations

Advanced structural designs, including multi-layered shells, porous matrix encapsulation, and three-dimensional thermal conduction networks, have shown promising results in enhancing overall thermal transport. These approaches focus on creating continuous thermal pathways while maintaining the structural integrity and phase-change performance of the encapsulated material.

Experimental Characterization Techniques

Accurate measurement of thermal conductivity in MPCMs requires specialized techniques due to their composite nature and temperature-dependent properties. Common characterization methods include transient plane source technique, laser flash analysis, and customized guarded hot plate apparatus. These methods provide insights into both the effective thermal conductivity and the underlying heat transfer mechanisms.

Transient Measurement Methods

Transient techniques offer significant advantages for characterizing MPCMs, as they minimize the impact of phase transition on measurement accuracy. The transient plane source method, in particular, has proven effective for measuring thermal conductivity across phase transition boundaries, providing valuable data for system design and optimization.

| Measurement Technique | Measurement Range (W/m·K) | Accuracy | Sample Requirements | Suitability for Phase Transition |

|---|---|---|---|---|

| Transient Plane Source | 0.01 - 500 | ±3% | Bulk samples | Excellent |

| Laser Flash Analysis | 0.1 - 2000 | ±5% | Disk-shaped samples | Good |

| Guarded Hot Plate | 0.01 - 10 | ±2% | Large flat samples | Moderate |

| 3ω Method | 0.1 - 100 | ±5% | Thin films | Limited |

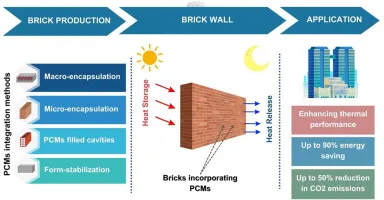

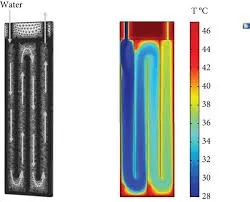

Applications and Performance Analysis

The enhanced thermal conductivity of modified MPCMs enables their application in various advanced thermal management systems. Key application areas include building energy efficiency, electronic cooling, solar thermal storage, and thermal regulation in textiles. The improved heat transfer characteristics allow for faster response times and higher power density in these applications.

Building Thermal Management

In building applications, MPCMs with enhanced thermal conductivity contribute to more effective passive temperature regulation, reducing energy consumption for heating and cooling. The improved thermal transport enables more rapid heat absorption and release, matching better with daily temperature fluctuations and occupancy patterns.

Electronic Thermal Protection

For electronic cooling applications, the high thermal conductivity MPCMs provide effective thermal buffering during power surges and transient operation. The enhanced heat spreading capability prevents localized hot spots and extends component lifetime while maintaining compact system dimensions.

Future Research Directions

Despite significant progress, several challenges remain in thermal conductivity modulation of MPCMs. Future research should focus on developing cost-effective enhancement methods, improving long-term stability under thermal cycling, and optimizing the balance between thermal conductivity, energy storage density, and mechanical properties. Emerging areas include smart MPCMs with tunable thermal properties and multi-functional composites combining thermal storage with other desirable characteristics.

Multi-scale Modeling Approaches

Advanced computational modeling spanning molecular dynamics to continuum scale simulations will play an increasingly important role in understanding and optimizing thermal transport in MPCMs. These models can guide material selection and structural design while reducing experimental optimization time and cost.

Conclusion

Thermal conductivity modulation in microencapsulated phase-change materials represents a critical enabling technology for advanced thermal energy storage systems. Through strategic material selection, nanoparticle incorporation, and structural optimization, significant improvements in thermal transport can be achieved while maintaining the high energy storage density characteristic of phase-change materials. Continued research in this field will unlock new applications and improve the efficiency of existing thermal management systems across multiple industries.