Types of Lens Coating for Glasses - Complete Guide

Introduction to Lens Coatings

Lens coatings are specialized treatments applied to eyeglass lenses to enhance their performance, durability, and visual clarity. These coatings serve various purposes, from reducing glare and blocking harmful UV rays to making lenses more scratch-resistant and easier to clean. Modern lens coatings have revolutionized eyewear technology, providing wearers with superior comfort and protection in various lighting conditions and environments.

Primary Types of Lens Coatings

Anti-Reflective Coating (AR Coating)

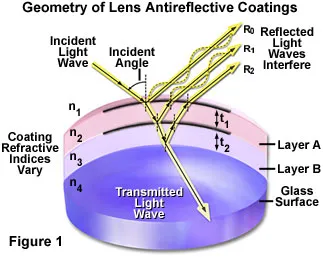

Anti-reflective coating, also known as AR coating or anti-glare coating, is one of the most popular and beneficial lens treatments available. This coating consists of multiple microscopic layers that reduce light reflection from both the front and back surfaces of lenses. By minimizing reflections, AR coating allows more light to pass through the lenses, resulting in clearer vision and reduced eye strain, especially during night driving or computer use.

Scratch-Resistant Coating

Scratch-resistant coatings create a hard, protective layer on lens surfaces that helps prevent scratches from everyday handling, cleaning, and accidental drops. While no coating can make lenses completely scratch-proof, these treatments significantly increase durability and extend the lifespan of your glasses. Most modern prescription lenses come with a basic scratch-resistant coating as standard protection.

UV Protection Coating

UV protection coatings block harmful ultraviolet radiation from reaching your eyes. Prolonged exposure to UV rays can contribute to various eye conditions, including cataracts, macular degeneration, and photokeratitis (sunburn of the eyes). While many modern lens materials offer inherent UV protection, additional coatings can provide enhanced coverage, particularly for clear lenses that don't automatically block UV light.

Anti-Fog Coating

Anti-fog coatings prevent condensation from forming on lenses when moving between temperature extremes, such as entering a warm building from cold outdoor air. These hydrophilic coatings work by attracting moisture and spreading it evenly across the lens surface, preventing the formation of water droplets that obscure vision. This is particularly beneficial for athletes, healthcare workers, and people who frequently transition between different environments.

Specialized and Combination Coatings

Blue Light Filtering Coating

With the increasing use of digital devices, blue light filtering coatings have gained significant popularity. These coatings are designed to block or filter high-energy visible (HEV) blue light emitted by digital screens, LED lights, and the sun. By reducing blue light exposure, these coatings may help alleviate digital eye strain, improve sleep quality, and provide additional protection against potential long-term retinal damage.

Mirrored Coating

Mirrored coatings, also known as flash coatings, create a reflective surface on lenses that reduces the amount of light entering the eyes. While primarily used in sunglasses for style and additional glare reduction, mirrored coatings can also be applied to prescription lenses. These coatings are available in various colors and reflection intensities, allowing for both functional benefits and aesthetic customization.

Hydrophobic and Oleophobic Coatings

Hydrophobic coatings repel water, causing moisture to bead up and roll off the lens surface, while oleophobic coatings resist oils and fingerprints. These coatings often work together to make lenses easier to clean and maintain. The water-repelling properties also contribute to the anti-fog effect and help keep vision clear during rainy conditions or when participating in water-related activities.

Lens Coating Comparison Table

| Coating Type | Primary Benefits | Ideal For | Durability | Cost Range |

|---|---|---|---|---|

| Anti-Reflective | Reduces glare, improves clarity, minimizes eye strain | Computer users, drivers, anyone wanting clearer vision | High (with proper care) | $$ |

| Scratch-Resistant | Protects against scratches, extends lens life | Everyone, especially active individuals and children | Very High | $ |

| UV Protection | Blocks harmful UV rays, protects eye health | Outdoor enthusiasts, people in sunny climates | Permanent | $ |

| Anti-Fog | Prevents lens fogging, maintains clear vision | Athletes, healthcare workers, mask wearers | Medium (may require reapplication) | $$ |

| Blue Light Filter | Reduces digital eye strain, may improve sleep | Heavy computer/device users, office workers | High | $$$ |

| Hydrophobic/Oleophobic | Repels water, resists smudges, easier cleaning | People in humid climates, those wanting low-maintenance lenses | Medium-High | $$ |

Advanced Multi-Coating Technologies

Multi-Layer Coatings

Modern premium lenses often feature multi-layer coating systems that combine several beneficial properties into a single treatment. These advanced coatings typically include anti-reflective, scratch-resistant, hydrophobic, and oleophobic properties in one integrated system. The multiple layers work synergistically to provide comprehensive protection and performance enhancement while maintaining optical clarity.

Photochromic Technology

While not strictly a coating, photochromic technology is often applied as a treatment to lenses. Photochromic lenses automatically darken when exposed to UV light and return to clear indoors. Modern advancements have improved transition speed and darkness levels, making them a popular choice for people who need vision correction both indoors and outdoors without switching between regular glasses and sunglasses.

Choosing the Right Coatings for Your Needs

Lifestyle Considerations

Selecting the appropriate lens coatings depends largely on your daily activities and environment. Computer professionals may prioritize anti-reflective and blue light filtering coatings, while outdoor enthusiasts might focus on UV protection and scratch resistance. Consider your typical day, hobbies, and any specific visual challenges you encounter when choosing coatings.

Cost-Benefit Analysis

While additional coatings increase the initial cost of glasses, they often provide long-term value through extended lens life, improved comfort, and better visual performance. Investing in quality coatings can reduce the frequency of lens replacement and provide daily benefits that justify the additional expense for most wearers.

Maintenance and Care of Coated Lenses

Proper Cleaning Techniques

Proper cleaning is essential for maintaining the effectiveness and longevity of lens coatings. Always use recommended lens cleaning solutions and microfiber cloths. Avoid using household glass cleaners, paper towels, or clothing to clean coated lenses, as these can damage the delicate coating layers over time.

Storage and Handling

Store glasses in a protective case when not in use to prevent scratches and damage to coatings. Avoid placing glasses lens-down on hard surfaces, and handle them with clean hands to minimize oil transfer. Regular professional cleaning and inspection can help maintain coating performance and identify when replacement might be necessary.

Future Trends in Lens Coating Technology

The future of lens coatings includes developments in self-cleaning technologies, enhanced durability through nanotechnology, and smart coatings that can adapt to different lighting conditions automatically. Researchers are also working on coatings with antimicrobial properties and improved environmental resistance for extreme conditions.